Understanding Brushless Tools

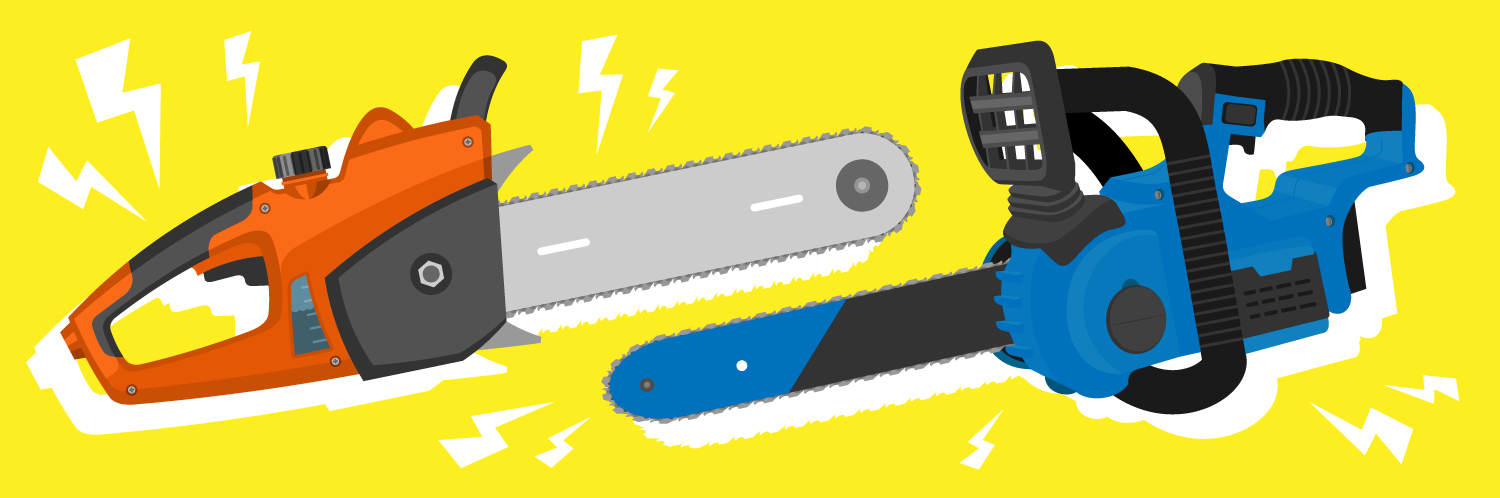

Technology tends to stay pretty much the same in the DIY world in which we all live. Sure we see new driver attachments that can remove even the most stripped screws, and other innovations that help simplify some projects a bit. But truly revolutionary changes tend to be few and far between. Enter brushless power tools.

New brushless options from the likes of Festool, Milwaukee, Hitachi, and Makita are still quite expensive, but as the price begins dropping on these tools, they will revolutionize the way you work.

- Looks like a normal drill. But the brushless motor offers many improvements to this Hitachi monster.

Here’s how a traditional power tool gets its power:

Magnets are mounted outside a motor’s armature. Inside an electromagnet constantly changes its polarity, thanks to contact between the brushes and commutator (on the outise of the armature), which allows the motor to spin. The commutator makes constant contact with the brushes and thanks to a little electromagnetic magic, the whole thing will keep going as long as you have power.

Now this system is good, but it does involve a lot of friction. After all, the brushes contact the commutator constantly. This friction leads to worn brushes and over enough time, worn commutators and armatures. It also puts more strain on the engine than is necessary.

But brushless drills change this model. Here’s how they work:

Things are reversed in a brushless motor. Manufacturers move the permanent magnets to the inside and the electromagnets outside the armature. The brushes and commutator are swapped out in favor of a computer chip that does the electromagnetic, pole-swapping magic itself. This results in pretty much no friction.

So now you have a non-engineer’s description of the differences between classic and brushless motors. But what does it mean for you?

I’m glad you asked.

Because brushless motors don’t need the commutator and brushes, they are lighter. Which means you will carry less weight up the ladder, and hold less weight in an awkward position as you drive one screw after another into a beam.

There’s also significantly less friction in these tools. This means your motor will last much longer. You’ll also get more work time on the same battery used in a classic tool, since less friction results in less battery consumption. And you’ll get more torque and power when driving.

And since a clean surface area where the commutator and brushes meet becomes less important, you’ll find your tool can hold up against the elements better than before. Check out this crazy video for some proof on that. We definitely don’t recommend you take your brand new brushless drill (or any tool) and put it through these tests. Still, pretty cool stuff.

Have you used a brushless drill yet? If so, share your experience with readers in the comments!