We Sell Only Genuine Ryobi® Parts.

Ryobi Electric Drill Replacement Parts by Model

Popular Ryobi Electric Drill Parts

Ryobi Electric Drill M Screw M4 X 10mm Ni Plated Ph

1 Review

Part Number:

6621202

In Stock

$4.99

It is a genuine item that is supplied by the original equipment manufacturer for use with Ryobi and Ridgid saws and dril...

Ryobi Electric Drill Strain Relief

1 Review

Part Number:

5927402

Usually ships in 7 - 12 business days

$3.99

Ryobi Electric Drill Bit Ph2 & S6 L50mm

5 Reviews

Part Number:

6782045

In Stock

$4.99

This is an authentic OEM approved part which is designed for use with Ryobi and Toro drills. It is an identical replacem...

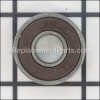

Ryobi Electric Drill Ball Bearing (6000lu)

6 Reviews

Part Number:

039176001012

In Stock

$4.99

It is an original manufacturer supplied replacement item and is sold individually. This ball bearing is sealed on both s...

Ryobi Electric Drill Ball Bearing (607zz)

Part Number:

039140001048

In Stock

$4.99

This authentic replacement part is designed for use with Ryobi power tools. Ball bearings are used to reduce friction be...

Ryobi Electric Drill Pressure Plate

Part Number:

513689001

In Stock

$3.99

Ryobi Electric Drill M Screw M4 X 10mm Ni Plated Ph

1 Review

In Stock

Part #Number:

6621202

$4.99

It is a genuine item that is supplied by the original equipment manufacturer for...

Ryobi Electric Drill Strain Relief

1 Review

Usually ships in 7 - 12 business days

Part #Number:

5927402

$3.99

Ryobi Electric Drill Bit Ph2 & S6 L50mm

5 Reviews

In Stock

Part #Number:

6782045

$4.99

This is an authentic OEM approved part which is designed for use with Ryobi and ...

Ryobi Electric Drill Ball Bearing (6000lu)

6 Reviews

In Stock

Part #Number:

039176001012

$4.99

It is an original manufacturer supplied replacement item and is sold individuall...

Ryobi Electric Drill Ball Bearing (607zz)

Part #Number:

039140001048

In Stock

$4.99

This authentic replacement part is designed for use with Ryobi power tools. Ball...