Because tool manufacturers often change power switch designs in their tools, using a tool or machine's model number isn't always the best way to find the right power cord.

Power cords are one kind of replacement part where it really helps to know exactly what you're looking for to get an accurate match. When shopping for power cords, customers should match the following to their old cord, spec for spec:

- gauge

- prong/end type

- fasteners/wire end

Power Cord Gauge Most power tool cords are between 12 gauge and 18 gauge, but the most common is 16 gauge. "Gauge" is short for American Wire Gauge (AWG), and is a system of measuring the diameter of cord or bundle of electrical wires. As the gauge number goes up, the diameter of the wire goes down and cords become smaller (thinner). As the gauge number goes down the diamter of the wire goes up and cords become larger (thicker). So, a 14 gauge cord is larger (thicker) than a 16 gauge cord, because the diameter of the 14 gauge cord is larger than the diameter of the 16 gauge cord. When shopping for a replacement power cord, first match the gauge of the new cord to the gauge of the old cord. A power cord's gauge is almost always written somewhere on it, usually with the abbreviation "AWG" right before the gauge number. [Back to top]

Power Cord Plug Types

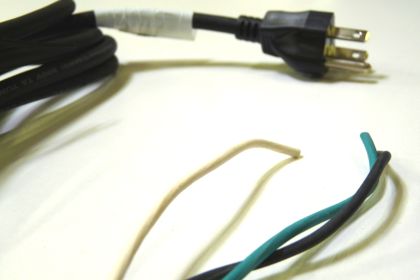

This seems an obvious feature to double check, but power cords are returned all the time after shoppers mis-match plug type and number of prongs on the plug. The two most common types of power cord ends are 2-prong and 3-prong. 2-prong and 3-prong cords have two and three wires respectively.

2-wire power cords protect the tool users from electrical shock with a system of double insulation. They end in two-pronged plugs and come in a variety of gauges.

3-wire power cords also protect tool users from shock. The third wire of the cord is a ground wire that directs any extra charge in the power tool away from the tool and away from the user. 3-wire cords end in three-pronged outlet plugs and also come in a variety of gauges.

The large majority of all power cords fall into the 2-prong or 3-prong categories, but there are still a couple more less widely-used power cord end types used out there that are worth mentioning.

Twist lock power cords are a kind of three prong cord designed to twist into a locked position after they are inserted into an outlet.

2-wire power cords protect the tool users from electrical shock with a system of double insulation. They end in two-pronged plugs and come in a variety of gauges.

3-wire power cords also protect tool users from shock. The third wire of the cord is a ground wire that directs any extra charge in the power tool away from the tool and away from the user. 3-wire cords end in three-pronged outlet plugs and also come in a variety of gauges.

The large majority of all power cords fall into the 2-prong or 3-prong categories, but there are still a couple more less widely-used power cord end types used out there that are worth mentioning.

Twist lock power cords are a kind of three prong cord designed to twist into a locked position after they are inserted into an outlet.

Twist Lock Power Cord Plug

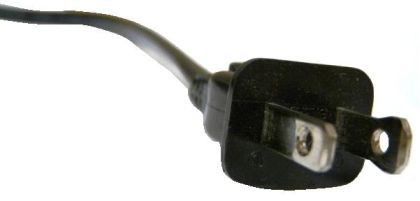

Milwaukee has also developed its own type of locking power cord system called the Quick-Lok system. Quick-Lok power cord ends look very different than conventional power cord ends.

Milwaukee has also developed its own type of locking power cord system called the Quick-Lok system. Quick-Lok power cord ends look very different than conventional power cord ends.

Milwaukee Quick-Lok Power Cord Plug

Obviously, your new replacement power cord won't be able to do its job of delivering power to your tool unless you match its end correctly.

[Back to top]

Obviously, your new replacement power cord won't be able to do its job of delivering power to your tool unless you match its end correctly.

[Back to top]

Power Cord Fasteners and Wire End Types

All replacement power cords end with exposed or partially-exposed wires that need to be installed into their tool's power switch. However, power cord wires install into power switches in a variety of ways.

Power cord wires often install into power switches using different fasteners. The power cord wire fastener type that a tool uses (if at all) depends on the kind of power switch that it has.

Again, because manufacturers tend to replace power switch units in their tool models often, it's best not to completely depend on the tool's model number to match the power cord.

In regard to matching the wire fastener type, this means that it's best to completely remove the old power cord from the tool before ordering a replacement.

By removing it beforehand, you can visually inspect the ends of the power cord wires to see what kind of fasteners it uses, and then you can ensure an accurate order.

Bare Wire Cords-

Bare wire cords sometimes come completely insulated, and sometimes the wires come with the insulation removed a little, ready for installation.

Bare wire cords don't use wire fasteners to install into power switches. Instead, they install via a variety of switch designs styles, like the "trap door" switch style (for example) that uses springs to hold bare wires in their switch terminals.

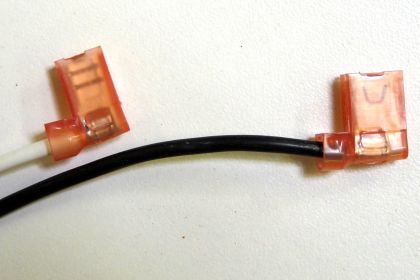

Eyelet Fasteners-

Some power switches are designed to have power cord wires installed using eyelet fasteners. Corresponding power cords often have the fasteners attached to the cord wires in advance.

It's possible to receive even an O.E.M. power cord that doesn't include the fasteners it needs, like eyelet fasteners.

If your tool's power switch requires wire installation with fasteners and you've purchased a power cord that lacks fasteners, take a fastener from the old cord to a hardwood shop and find a match real quick by eyeballing it.

The fasteners will be inexpensive and easily installed with a quick squeeze from some pliers.

Other Wire Terminals-

After the much more standard eyelet type of wire fastener, power cord fasteners quickly become more complicated.

There are a number of specialized fasteners in use by manufacturers that are designed to only fit into certain corresponding slots on specific power switches.

Obviously, special terminals promote O.E.M. parts replacement (a good idea anyway), but they also mean that you need an exact cord replacement match if your cord uses special and/or proprietary fasteners.

[Back to top]

Conclusion

After matching these three major power cord compatibility features--gauge, plug, and wire ends--all that's left to do is select the length of cord that you want and any additional features the power cord might have.

Replacement power cords need to match the tools they connect to, the outlets they plug into, and the right thickness (gauge) needed to deliver power.

Visit our Power Cords page here at eReplacementParts.com. You can narrow power cord searches by selecting only the specifications you need for your tool.

You can get tool's replacement cord by visiting its parts page. Enter your tool's model number in the search field at the top-left of this page and you will be directed to its parts list and breakdown diagram.

As long as the the tool's model number, type number, and other identifying marks match up, the power cord displayed on its parts page will be a perfect match.

[Back to top]

What we're about.