Why Read This Article?

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Article Breakdown

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Because there's so much crossover between applications, sizes, and materials, the tidiest way to approach the enormous tangle of drill bit variation is to categorize them by design.

Below are brief descriptions of the most common drill bit types, their applications, and their strengths/weaknesses. But before discussing specifics, we'll start with some very basic information about drill bits in general.

Masonry and other hammer drill bits are not discussed in this article, because they can be a complicated enough subject on their own. Click this link for more information about Masonry Bits.

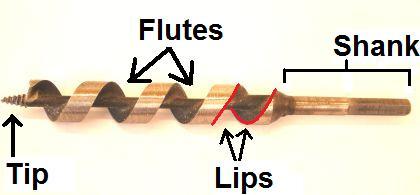

Parts of a Drill Bit

With only a few exceptions, most drill bits share the same basic parts and terminology for those parts.

Being familiar with drill bit parts and part names is important for accurate ordering and understanding how each bit design is manufactured for its specific job.

The major parts of a drill bit are:

Shank-

A bit's shank is the non-working end of the bit that fits into the drill chuck. Shanks are almost always perfectly round, and sometimes include design features that reduce bit slippage in the chuck.

Lip(s)-

The lip or lips of a drill are the cutting edges of the bit. Drill bit lips can be positioned in different places on the bit, depending on the bit design and application.

Flute(s)-

These are the grooves in a drill bit that allow and direct the ejection of material as it leaves the hole being drilled. Bits for faster, coarser drilling and "boring" bits have wider, deeper flutes for faster material ejection. Flutes are also commonly called "chip channels."

Tip-

Easy enough. The tip of a drill bit is the working end of the bit opposite of the shank.

Misc.-

Some drill bit parts are specific to certain bit designs as is discussed below. The blade of a spade bit is one example of this.

[Back to top]

Drill Bit Sizes and Measurements

Bit sizes and measurements might be the area where drill bits see the most variation, but even so, most drill bits still have several measurements in common that are used to identify them.

After knowing what bit design and other features are needed for an application, measurements like bit length and diameter are necessary to further match a bit to its job.

Here are the most-commonly shared drill bit measurements:

Bit Diameter-

This is the diameter of the working end of the drill bit, or its tip.

Shank Diameter-

Accordingly, this measures the diameter of the bit shank that fits into the chuck.

Overall Length-

Length of the entire bit, shank included.

Flute Length-

The overall length minus the shank length. In other words, just the cutting portion of the bit.

Misc.-

Some bit designs include measurements specific to that design that are also used for identification and compatibility matching. For example, step bits also have a "smallest/largest diameter" measurement and an "increment" measurement.

[Back to top]

Drill Bit Materials

A given size and type of drill bit will often be available in several materials, another purchasing option to consider.

Drill bit materials offer users varying degrees of wear-resistant toughness, strength, lasting sharpness, and otherwise unavailable drilling options (like through hard metals).

The most important factor to consider when choosing a bit material is the application material. A carbon steel bit may be able to cut through some metal materials, but this may also cause heavy wear on the bit.

As bit materials get harder they grow more expensive and brittle. Users can save themselves money by choosing bit material carefully. Overshooting can mean paying for expensive bits that aren't needed, while undershooting the issue can burn through bits in an equally expensive way.

Available materials for drill bits:

Carbon Steel-

Low and high carbon steel bits are the most inexpensive and the most common. Great for softer wood materials and plastics, these bits perform great when they're not overworked. Using carbon steel bits on harder woods and metal will cause them to wear quickly.

High Speed Steel (HSS)-

High speed steel bits go through an additional tempering process that hardens them. This process upgrades traditional carbon steel bits so they can drill through some metals. All in all, HSS bits last longer and can cut through harder materials, but excessive heat during use can damage them, as heat undoes the hardening effect of their tempering process.

Cobalt Steel-

By mixing higher concentrations of cobalt into the steel alloy, cobalt steel bits improve upon high speed steel bits with a greater degree of hardness that can withstand high temperatures. This lengthens the life of the bit considerably, especially when used on metals and other hard materials. The only disadvantage is an increase in brittleness, but when used correctly, these will outperform and outdistance other steel bits.

Titanium Coated-

Titanium ceramic coatings are used to coat some drill bits. This addition can make them three to five times longer lasting than HSS drill bits, and also helps keep the cutting edges of the bit sharp. However, titanium coated bits cannot be sharpened without losing the benefit of their coating.

Carbide-

Carbide bits are often "tipped" much like titanium bits. Carbide is an extremely hard material, making these bits the hardest of them all and the most expensive. When needed for stainless steel and other hard metals, no other bit can keep up in performance and durability.

[Back to top]

Drill Bit Types

Many design details work together to fit a drill bit to its application.

The aggressiveness of bit, how fast it ejects material, its target material, and drilling speed are determined by things like how much twist is in the bit, its tip angle, and lip angle.

Specialty bits have more drastic design changes, and sometimes need a little extra information for purchasing.

Twist

Twist drill bits (sometimes called "Morse" bits) are the most common, and are probably the bits that users are most familiar with since they're the most general-use drill bits (although, most manufacturers are currently switching to split point point bits).

Twist bits are designed for fast drilling and are best for metal applications. They can be used on wood, but their speed often causes "tear out" at the bottom end of the hole. Bits like brad point bits are specially designed for more delicate woodworking drilling.

[Back to top]

Split Point

These are a variation of the twist bit. The cutting edges of split point bits are sharpened a little more narrowly at the tip, and at a different angle. This feature adapts the bits for metal drilling, even stainless steel.

Their design helps to prevent "walking," the de-centering of the bit when the drill is fired up that often occurs with metal drilling. Because split point bits are designed for metal drilling, they are readily available in hard bit materials like cobalt steel and carbide.

[Back to top]

Brad Point

For woodworking applications, brad point bits also go by the names "lip and spur" bit and "doweling" bit.

Brad point bits usually come to a sharp point at the tip for self-centering, and also have "spurs" or "brads" along the outside of the bit tip, the bit's cutting edges. After the hole is started, the lips on the outside of the bit cut the hole from the outside in. This makes a much cleaner hole, especially where the bit exits the work.

[Back to top]

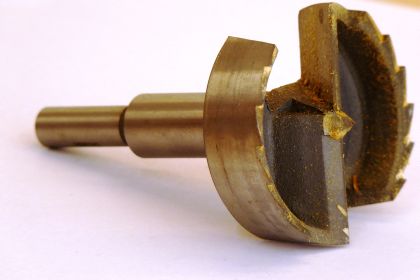

Forstner

Forstner bits are the big grandaddy drill bits for wood drilling. Their flatter cutting edges span the length of the bit's diameter, planing wood out of the hole as it cuts.

These are the largest bits for wood drilling and are often used on drill presses. But, self-centering forstner bits are available, and are much more suited for handheld power drill use.

Like other self-starting bits, forstners with a self-starting feature will come to a small point before the main body of the bit tip begins.

[Back to top]

Auger (self-feeding)

Used mostly by plumbers and electricians, auger bits are made for boring long holes through wood. They are designed with deep, wide flutes for extra-fast material clearing, and cut coarse holes.

Like other self-starting bits, forstners with a self-starting feature will come to a small point before the main body of the bit tip begins.

[Back to top]

Auger (self-feeding)

Used mostly by plumbers and electricians, auger bits are made for boring long holes through wood. They are designed with deep, wide flutes for extra-fast material clearing, and cut coarse holes.

Often, auger bits are needed to drill holes across framing studs for things like wiring, meaning that auger bits can also be very long.

Most auger bits have a small tip at the end for self-feeding, accurate centering, and faster drilling.

[Back to top]

Spade

Spade bits are also called "paddle" bits, and are used for fast, rough wood boring. Cutting edges are placed on the sides of the spade blade, and they also have a small point at the center of the bit to guide the drilling.

[Back to top]

Pilot Point

Developed by DeWALT, these metal drilling bits include a miniature split point bit at their end. This tip allows the bit to drill a preliminary starter hole in the metal material and continue through with the rest of the hole all in one action without bit changing.

[Back to top]

Bell Hanger

Also called "fishing" bits and "installer" bits. A bell hanger feature can be added to several designs of drill bits just by adding a small hole in the bit near its tip.

The holes at the end of bell hanger bits are for pulling wires through recently drilled holes for installation.

[Back to top]

Countersink

These are a specialty bit for making countersink holes, a preliminary hole that allows the head of a screw to sit profile or beneath the level of the material.

Each countersink bit is made to match a specific screw head angle. The tip of the bit is a twist bit that starts the hole in which the screw will be set. The twist bit is followed by a cone shaped bit that bores out an indention for the screw head.

[Back to top]

Hole Saw

Hole saw bits are wood drill bits that act a lot like a saw. They cover medium size drilling needs that are bigger than those that auger bits handle and smaller than those in the jurisdiction of the larger forster bits.

Hole saw bits are divided into two parts. The bottom part is called the "mandrel" and fits into the chuck; it includes a standard twist bit in the middle for starting and guiding the hole. The rest of the bit fits onto the mandrel. Each mandrel has a specific thread size for bit compatibility, and a specific shank size and style.

The outer part of the hole saw bit is a ring of saw teeth that cut out a plug-like hole. By only cutting the outside ring of the hole, the hole saw's design cuts down on the power needed to cut large holes, making them perfect for handheld power drill use. Also, hole saw holes are very smooth.

[Back to top]

Step Drill

Step bits are some of the most interesting and complicated drilling bits. They are designed so that users can drill several different hole sizes without changing bits, primarily in metalworking.

Step bits have a tiered series of cutting edges that increase the bit diameter in specific increments. Because of this design, there are several additional measurements that should be considered when buying a step bit.

Additional step bit measurements include: its smallest diameter, its largest diameter, the size of increments between its steps, the number of hole sizes it has, and the depth of its steps.

[Back to top]

Conclusion

Visit eReplacementPart.com's Drill Bits page for huge selection and variety of drill bits, including specialty bits.

Each drill bit page includes a search filtering feature for narrowing down the exact design, size and material of your drill bit order. Start with the desired bit design, and then work through other options like material and bit diameter.

[Back to top]

What we're about.