How Do Electric Motors Work?

Electric power tools are extremely handy devices to have on hand around the shop or in the garage, and their maintenance requirements are generally pretty routine. For everyday use, you just plug them in or charge the battery, and away you go onto your next project. But have you ever stopped to wonder how the electric motor in your power tool works?

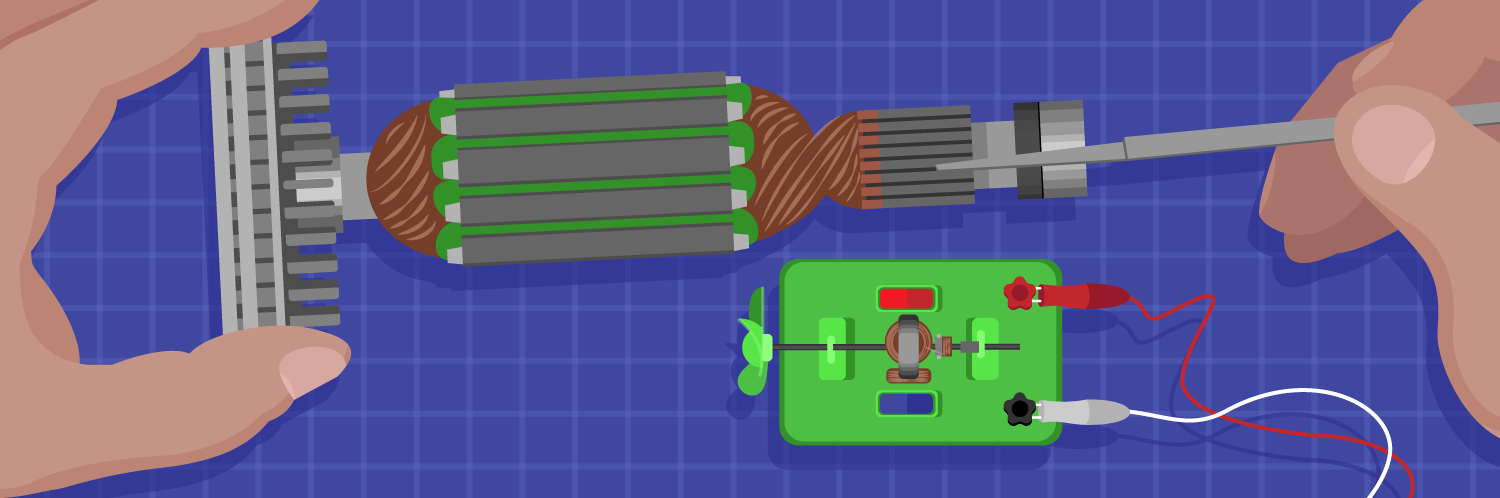

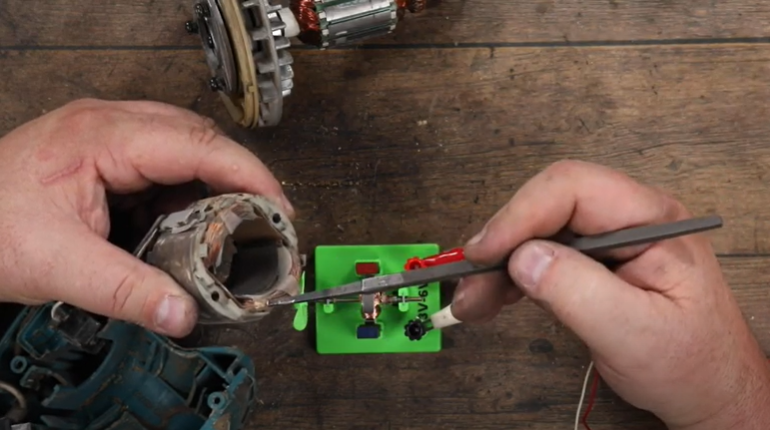

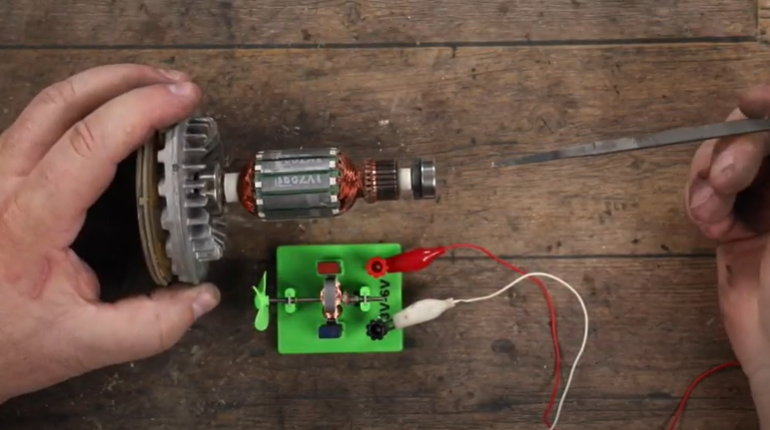

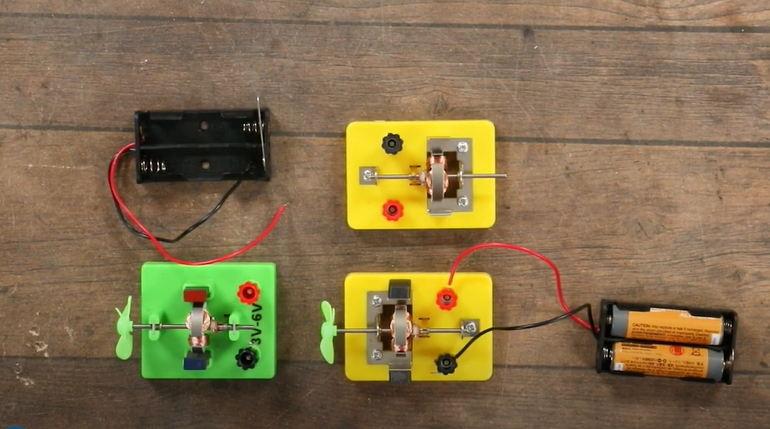

In this video and article, we constructed a basic electric motor to demonstrate how one operates. We’ll compare the parts on our model to the full-sized parts commonly found in power tools and explain their different functions. Following that, we’ll cover what torque is and how that applies to your power tools.

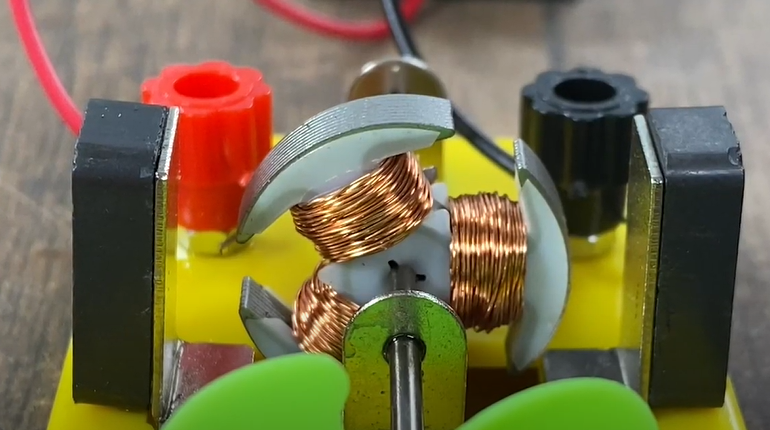

The first part we’re going to look at in an electric motor is the stator which is represented by two magnets on our model. The stator is made up of multiple windings, and when power is supplied it creates an electromagnetic field. It helps to drive the rotation of the armature. Fixed or permanent magnets can also be used to create the magnetic field, but fixed magnets will weaken over time, whereas an electromagnetic field is created whenever the power tool is in use.

The armature is the main shaft in our electric motor and carries alternating current. When power is supplied and the stator creates the electromagnetic field, this field creates a force that causes the armature to rotate. The rotation is a result of electrical energy being converted into mechanical energy.

As we learned in grade school, magnets have north and south poles and opposite poles attract. The north pole of the armature is attracted to the south pole of the stator, which creates the force that causes the armature to spin. To keep the armature rotating in one constant direction, commutation is needed. As we stated above, the current between the stator and the armature is alternating. The commutator is used to convert it to direct current, which ensures that the torque is always being applied in the same director. The commutator does this by switching the direction the magnetic fields are pointing towards. Without the switching, the armature would rotate 180 degrees in one direction and then go back in the opposite direction. By changing the magnetic fields, constant rotation in one direction is achieved.

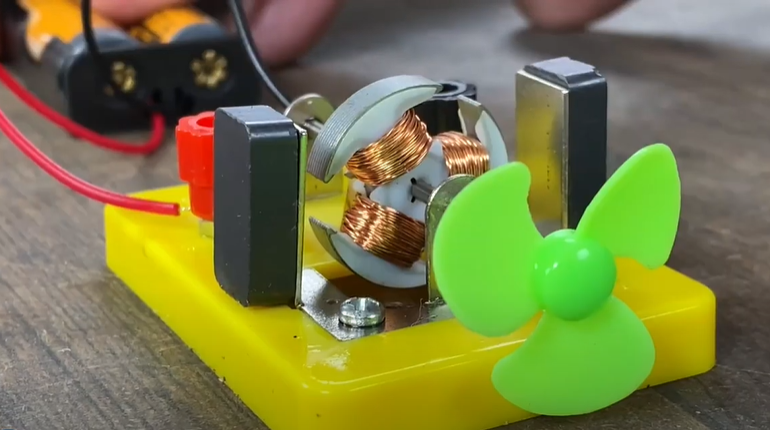

When batteries (a power supply) are connected to our model electric motor, you can see how the entire process works, resulting in the propellor spinning. A magnetic field is created, and as the armature spins, the commutator connects to different windings, creating different poles. The constant attracting and repelling allows the armature to rotate in one direction. In our model, it’s the prop that spins, but on your different power tools, this could be represented by drill bits, angle grinder wheels, or an orbital sander.

So, What is Torque and How Does it Apply to Power Tools?

The Short Answer

The short answer is torque is the strength to turn or rotate a particular item. The official definition states that torque is a measure of how much a force acting on an object causes that object to rotate. If you think of a torque wrench, it allows you to apply more force on a nut to tighten it down. Or when it comes to power tools, more torque allows a drill to easily power through the material it is drilling.

What Makes Torque?

As we learned above with our model motor, the electromagnetic field formed by the magnets created enough force, or torque, to rotate the armature. To create more torque, we need to increase the power of the magnets. We can do this by using stronger magnets or by increasing the windings. More windings = more magnetic force created = more power = more torque.

The Long Answer

When current goes through a wire, it follows something called the right-hand rule (used to determine the direction of the magnetic force on a positive moving charge). The more loops you put that force through, the more it will build up, creating more power. If we want more power, the diameter of the wire will need to increase, as that allows more current to pass through. You can essentially create a super magnet with an incredible amount of torque, however that motor will end up being quite large in size. Generally speaking, smaller motors have less torque and larger motors have more.

What About Horsepower?

In reference to motors, horsepower is a unit of measurement of power. Horsepower (hp) is a factor between revolutions per minute (RPM) and torque to determine the rate at which work is done. It is possible to have a motor with a lot of horsepower that spins slowly, but has incredible torque or the opposite where it rotates incredibly fast but with little torque behind it. When determining what kind of motor is best for your needs, you’ll want to look at all the components, not just the horsepower, as that number alone won’t tell you the full story.

If you need replacement parts to keep your power tools running smoothly, we have you covered! Search for your model number and find the exact OEM replacement part you need. Be sure to follow our YouTube channel so you don’t miss any of our repair tips.