Genuine Porter Cable replacement part, this item is sold individually.

Head Gasket Sold Separately.

This part is used in the all of the compressors models listed below.

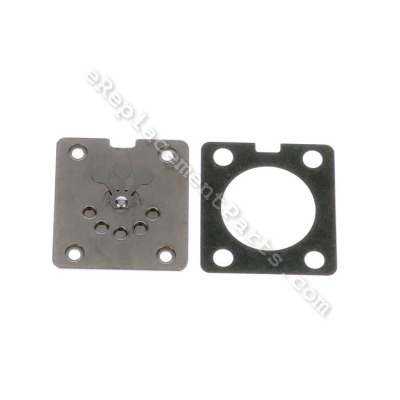

When air is pumped by the piston it passes through the Valve Plate into the compressor tank.

There are reeds on the valve plate that will eventually wear out, and the Valve plate will need to be replace.

It is advisable at this time to replace the Graphite Gasket Kit, part number D30139.

Valve Plate With Lower Gasket N017592SV

OEM part for: Porter Cable, Delta, DeWALT, DeVilbiss, Black and Decker, Craftsman, Bostitch, Stanley, Husky

Part Number: N017592SV

Jump To:

Product Description ?

- Classification: Part

- Weight: 0.25 lbs.

- Shipping: Ships Worldwide

Frequently Purchased Together ?

Compatibility

This Valve Plate With Lower Gasket will fit the following 308 machines. Confirm this part works with your model, and view the detailed model diagrams and repair help we have to offer.

Porter Cable

Delta

DeWALT

DeVilbiss

Black and Decker

Craftsman

Bostitch

Stanley

Husky

Show More Compatible ModelsThis item works with the following types of products:

- Compressor Parts

This part replaces obsolete part #: N017592, Z-A08548

Repair Videos ?

|

Expertly and economically remove and install the valve plate assembly on an air compressor. ...

November 20, 2014

|

Customer Part Reviews ?

- 1

- 2

- 3

Questions & Answers ?

Our customer Service team is at the ready daily to answer your part and product questions.

Ask our Team

We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

Does this fit my product?Questions & Answers for Valve Plate With Lower Gasket

Customer Repair Instructions ?

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part.

My compressor started leaking air!

Tool Type

Compressor

Difficulty

Medium

Time

30-60 minutes

Tools Used

Screwdriver, Pliers, Socket set, Long Allen wrenches

blown head gasket

Tool Type

Compressor

Difficulty

Easy

Time

30-60 minutes

Tools Used

Screwdriver, Pliers, Nutdriver, 1/4 drive ratchet

While using the machine, it started making a strange noise and refused to develop pressure.

Using a socket drive I disconnected the high pressure hose exiting the motor/pump cover going to the one way check valve mounted on the tank.

Using a Philips head screwdriver, I removed the two screws holding the housing in place near the tank brackets.

Using a torx driver I removed the screws holding the two motor/pump cases together, pushed the assembly forward from the mounting brackets and then separated the plastic cases.

There are rubber mounting feet placed at various locations keeping the pump and motor mounted to the plastic cases. Be certain to retain all of these square feet. If one or more are lost, they are available at this site as a separate part number.

Once again, using a nut driver, I removed the pump head (four screws) and separated the gaskets, valve assembly and O-ring. This is when I discovered the missing piece of head gasket. As the parts were so inexpensive, I ordered everything except the head casting itself.

The gasket kit I received had a replacement gasket to go with the new valve assembly that no longer used the O-ring. The gasket kit contained an O-ring had I used the old valve assembly.

Installing the head required using a cross-tightening pattern for installing the head bolts. As I had no specifics regarding the actual torque suggested for the head bolts, I tightened them to a level I thought appropriate without stripping the cylinder threaded holes.

Re-assembly was a reversal of the process listed above.

Silly me! Had I known the repair was going to be successful, I would have ordered motor brushes as they are worn more than half way and are only another $20. Now I need to order additional parts and separate the motor/pump casing halves again in order to replace the brushes.

KL

The compressor wouldn't build pressure.

Tool Type

Compressor

Difficulty

Easy

Time

15-30 minutes

Tools Used

Screwdriver, Pliers, Socket set, Nutdriver, Adjustable Wrench, Thread seal tape

The valve plate had a broken tab, which was causing the air compressor to run without building pressure.

Tool Type

Compressor

Difficulty

Easy

Time

15-30 minutes

Tools Used

Socket set, Nutdriver

Parts Used

Removed the motor and then removed the head gasket.

Then removed the defective part and installed the new one.

Put it all back together and it runs like a new one.

It holds pressure without any leak down.

Thanks ereplacementparts for quick shipping and quality part. You made my life easier and if I can do it anyone can. I will definitely use you for all of my future repairs.

leaking air

Tool Type

Compressor

Difficulty

Easy

Time

15-30 minutes

Tools Used

Screwdriver, Pliers, Torx drivers

compressor not building pressure quickly

Tool Type

Compressor

Difficulty

Medium

Time

30-60 minutes

Tools Used

Screwdriver, Power Drill, Socket set, Nutdriver, na

Parts Used

one of the 3 valves was broken in head.

Tool Type

Compressor

Difficulty

Medium

Time

30-60 minutes

Tools Used

Screwdriver, Pliers, Socket set, Wrench Set, Adjustable Wrench, torque wrench in.lbs.

reed valve was broken

Tool Type

Compressor

Difficulty

Easy

Time

1-2 hours

Tools Used

Socket set, Nutdriver

compressor not building pressure

Tool Type

Compressor

Difficulty

Medium

Time

15-30 minutes

Tools Used

Screwdriver, Wrench Set

Parts Used

2. removed retaining screws on bottom of plastic case to slide compressor out of position

3. open plastic case by removing screws holding case hales together

4. removed copper air line. Faulty airline seal evident.

5. removed four hex head screws at top of cylinder

6. replaced valve, gaskets after cleaning and inspecting cylinder for wear.

7. Note: clean air line and position new air line gasket on tube first, then insert gasket and tube in cylinder head recess for gasket. Inserting tube after assembly is almost impossible.

8. assembly is reverse of disassembly

Compressor not building air

Tool Type

Compressor

Difficulty

Easy

Time

30-60 minutes

Tools Used

Screwdriver, Socket set

Parts Used

OEM stands for Original Equipment Manufacturer and means the part you’re buying is sourced directly from the manufacturer who made your product. At eReplacementParts, we sell only genuine OEM parts, guaranteeing the part you’re purchasing is of better design and of higher quality than aftermarket parts.

Our product descriptions are a combination of data sourced directly from the manufacturers who made your product as well as content researched and curated by our content & customer service teams. This content is edited and reviewed internally before being made public to customers.

Our customer service team are at the ready daily to answer your part and product questions. We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

All our part reviews are solicited directly from other customers who have purchased this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

Based on data from past customer purchasing behaviors, these parts are most commonly purchased together along with the part you are viewing. These parts may be necessary or helpful to replace to complete your current repair.

All our installation videos are created and produced in collaboration with our in-house repair technician, Mark Sodja, who has helped millions of eReplacementParts customers over the last 13 years repair their products. Mark has years of experience in selling and repairing both commercial and residential products with a specialty in gas-powered equipment.

This data is collected from customers who submitted a repair instruction after replacing this exact part. Customers can rate how easy the repair was to complete and how long it took. We aggregate this data to provide a repair rating that allows customers to quickly determine the difficulty and time needed to perform their own repair.