Why Read This Article?

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Article Breakdown

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Safety Guidelines

- Do not ever put your hands in the discharge chute of a snowblower.

- Only clear snowblower chutes with a breaker bar or some other object after the machine is turned off.

Owners should also expect to replace certain parts over the course of their snowblower's life, parts specific to snowblowers that are designed for wear and eventual replacement.

This article discusses how to care for and maintain snowblowers, how to prevent unnecessary wear to expensive snowblower parts, and what to look for when its time to replace those less expensive, wear-prone parts.

Snowblower Safety Tips

Although this is article is not strictly about safety, it would be irresponsible not to mention this one major snowblower safety concern.

Snowblower discharge chutes can become clogged with snow during operation, often tempting users to use their hands to unclog the chute.

Here's the tip:

- Do not ever put your hands in the discharge chute of a snowblower.

This is especially dangerous with two-stage snowblowers, since most two-stage snowblower impellers are always spinning, even when at idle. The impellers of single stage machines may not spin at idle, normally, but it would only take the tiniest of mechanical slips for that impeller to engage itself and eat a hand for dinner.

We recommend against using hands to clear discharge chutes even if the snowblower is completely turned off, because it's just a terrible habit to reinforce.

Many snowblowers come with some kind of breaker bar for clearing jammed chutes. If one isn't available, a broom handle or some other object can be used. Snowblowers should still be turned completely off before clearing their chutes in this way.

Here's the other tip:

- Only clear snowblower chutes with a breaker bar or some other object after the machine is turned off.

Engine service should include:

- checking and topping off the oil level before each use.

- cleaning excess oil and dirt from the motor.

- tightening screws, belts, and other parts.

- cleaning or changing filters.

- changing spark plugs.

- lubricating cylinders, and

- correctly treating fuel for storage.

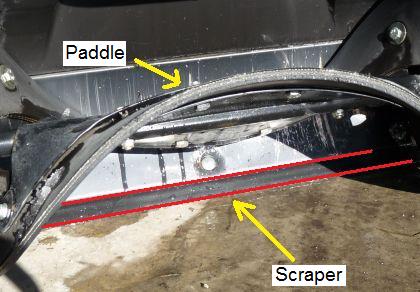

All snowblowers work by propelling themselves, cutting up the snow beneath them, lifting that snow, and then forcefully ejecting it. Single stage snowblowers do all of this in one smooth mechanical motion. They do not have separate augers (for cutting) and impellers (for lifting) like two-stage snowblowers. Instead, single stage snowblowers do both jobs by cutting and throwing the snow all at once with their specially-shaped cutting impellers. Single stage impellers are sometimes called "paddles," and they are also responsible for propelling the snowblower as they dig into the snow. Generally, single stage snowblowers are designed to efficiently handle snow clearing up to 12" deep. Single Stage Wear Parts There are only two major wear parts for single stage snowblowers, but they can last for many years despite the fact that they are designed for replacement. As discussed further below, replacing these parts on schedule reduces the risk of damaging more expensive parts during operation.

Impeller/Paddle-

Most single stage impellers are made of (or covered with) some type of hard plastic or rubber that wears width-wise over time from friction associated with normal use.

Check the snowblower's paddle a couple of times each season just to be sure it's not ready for replacement. An impeller should be replaced after it has worn somewhere between 3/8" and 1/2" along its width from its original width.

One easy way to diagnose a bad impeller is by any changes in how far the machine throws snow. If a snowblower suddenly ejects snow at a shorter distance than it used to, chances are that the impeller has gone bad.

Scraper-

Both kinds of snowblowers have scrapers somewhere behind their cutting ends that help to accumulate snow in the auger/impeller housing.

Like impellers, scrapers will gradually suffer from wear with normal use and should be replaced.

The thickness of scrapers will wear down as they grind against the ground and/or snow, so users can look for thinning. Scrapers often wear in curved patters as well, especially when a snowblower is used to clear snow on a slanted or contoured area.

Scrapers on single stage snowblowers are usually made of nylon or some kind of hard, black plastic.

Conveniently, snowblower impellers and scrapers tend to require replacement at about the same time.

[Back to top]

Two-Stage Snowblowers and Parts Replacement

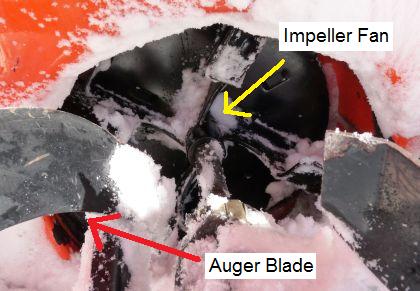

Two-stage snowblowers are generally larger than single stage units, and they also split up the jobs of propelling, cutting, and throwing snow between separate parts.

Most benefit from independent tire drive powered by their motors.

Cutting is accomplished by a number of metal, spiral shaped auger blades that chop the snow up and lift it to the machine's impeller. The impeller fan is separate from the auger blades, and works to eject the chopped snow out the discharge chute.

Although impeller and scraper wear is also a concern for two-stage units, these larger snowblowers have a couple of additional wear parts that require attention and replacement.

Two-stage snowblowers are generally built to efficiently handle snow clearing up to about two feet deep.

Two-Stage Wear Parts

Replacing snowblower parts on schedule will do more than ensure good machine performance, it will prevent more expensive parts from being damaged.

It's much better to throw on some new skid shoes or a fresh scraper than having to replace expensive auger blades or an entire auger housing.

Impeller-

Two-stage impellers wear less quickly than single stage impellers, because they are deeper in the machine and do not contact the ground, and also because they are usually made of metal.

However, two-stage impellers can still see wear over the years and stop throwing that snow as far as they used to, so it's best to check them occasionally.

Scraper-

Two-stage snowblower scrapers are usually made from steel, but they will eventually encounter the same kind of wear that single stage scrapers see.

Look for significant reduction in the scraper's overall thickness (comparing to its original thickness), and also check for curved wearing patterns.

Shear Pins-

Two-stage snowblower impellers and augers are partially held in place by little bolts called shear pins. These pins are actually designed to break under the strain of a specific level of torque, such as when something jams up the turning auger blades.

When a snowblower shear pin breaks because of some obstruction in the working end of the machine, the auger blades stop turning and the much more expensive engine gears are saved from demolishing themselves under their own power.

Most two-stage snowblower owners will experience a shear pin break in the course of their machine's life.

It is extremely important that snowblower shear pins be replaced with Original Equipment Manufacturer (O.E.M.) parts. These pins must be perfectly engineered to match the torque breaking level specific to each snowblower in order to work correctly.

If the pins are too brittle, then they will just keep breaking in low stress situations over and over. If the pins are too durable, then they put the snowblower's gears at risk by failing to break when they are most needed.

Skid Shoes-

One of the worst things that could happen to a snowblower during operation would be for the spinning auger blades or the housing to contact cement or asphalt.

Because two-stage snowblowers do not rely on their auger blades to pull the machine, they have additional parts mounted on the sides of the the auger housing that lift the housing and the auger blades off of the ground at various settings. These parts are called skid shoes.

The idea is that since something has to take the brunt of all that ground friction, it might as well a less expensive part like skid shoes that can be easily replaced.

If skid shoes are allowed to wear all the way down, then snowblower owners are looking at some very expensive auger blade and/or housing replacements in the near future.

The best thing to do is to keep an eye on skid shoe wear by checking them with each blower use. Most skid shoes will have some kind of protruding flange on their bottoms. If the flange is gone, then you know that a skid shoe replacement is far past due.

Unfortunately, it is not uncommon for users to neglect these parts until they have worn all the way down to the screw holes where they attach to the housing, in which case, the entire housing must be replaced. [Back to top] Preventing Heavy Wear to Snowblower Parts Preventing damage to a snowblower's more expensive parts mostly just involves correctly replacing the wear parts already discussed in this article. Fresh scrapers and skids, for example, will keep the machine's augers and housing off of the ground where they're sure to get shredded.

Here's the short list of wear and damage prevention tips:

- Never allow the auger blades to touch the ground.

- Replace scrapers on schedule.

- Replace skid shoes on two-stage snowblowers before they wear to the level of the housing.

- When replacing shear pins, make sure that they are O.E.M. parts.

- Do not allow sand, gravel, or other high-grit material to enter the snowblower. (Two-stage impellers are often ruined this way.)

- For extra wear prevention, set the snowblower's scraper to ride just above the ground (about 1/8"). Many users prefer to set their scrapers to ground level, which is fine, but doing so will increase the rate of wear to the part.

[Back to top] What we're about.