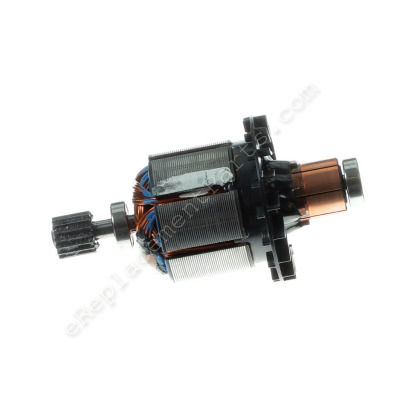

This replacement armature is specially produced for Dewalt drills/drivers. It is supplied directly from original equipment manufacturer and it is sold individually. If you notice smoke or sparks coming from the vents on the back of your tool, you've probably overloaded your armature at some point, which caused the insulation to break down. If you see sparks or smoke, do not use your tool again until you perform an armature repair. Due to constant contact with carbon brushes armature will eventually wear out and would need to be replaced. It is highly recommended to replace both carbon brushes when replacing an armature.

Remember to be especially careful of the armature fan when you remove it, because if you break it, you will have to replace the entire armature. This item includes an armature, fan, armature bearing and commutator end bearing.

To replace this armature you would need a screwdriver.

Armature Assembly N023147SV

OEM part for: DeWALT

Part Number: N023147SV

Jump To:

Product Description ?

- Classification: Part

- Weight: 0.45 lbs.

- Shipping: Ships Worldwide

Frequently Purchased Together ?

Compatibility

This part will fit the following 24 machines

DeWALT

This item works with the following types of products:

- Drill Parts

- Hammer Drill Parts

This part replaces obsolete part #: N023147, 658386-00

Repair Videos ?

|

This article explains how to hot-wire test a cordless drill motor with step-by-step instructions and a demonstration vid...

September 30, 2009

|

Customer Part Reviews ?

- 1

Questions & Answers ?

Our customer Service team is at the ready daily to answer your part and product questions.

Ask our Team

We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

Does this fit my product?Questions & Answers for Armature Assembly

Customer Repair Instructions ?

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part.

The plastic ring around the armature was broken.

Tool Type

Cordless Drill

Difficulty

Easy

Time

Less than 15 minutes

Tools Used

, T-10 and T-15 torque drivers are all you need.

Parts Used

The Armature blew up So I ordered a new Armature and brushes replaced it and it works fine save me 300 bucks

Tool Type

Cordless Drill

Difficulty

Easy

Time

15-30 minutes

Tools Used

, Torques Wrench

Parts Used

armature burned out /brushes bad

Tool Type

Hammer Drill

Difficulty

Easy

Time

15-30 minutes

Tools Used

Screwdriver, Torx head screwdrivers

Armature overheated, tore up the brushes and holder

Tool Type

Cordless Drill

Difficulty

Medium

Time

30-60 minutes

Tools Used

Screwdriver, Torx drivers

2. Separated driver end and housings

3. Removed motor hold downs

4. Removed assembly and replaced with new parts

5. Reinstall all parts and test

Motor burnt

Tool Type

Cordless Drill

Difficulty

Medium

Time

30-60 minutes

Tools Used

Screwdriver, Pliers, Torx screwdriver

Remove remaining screws holding clamshell together

Separate clamshell and gear assembly may need to pry a little bit be sure all screws are removed

Once separated u will need to remove bearing cap screws then lift out mag ring armature and brush assembly

Assemble in reverse order being cautious of mag ring clocking it only goes in on way with notch on the end facing chuck

This repair can be frustrating but with any mechanical ability it can be done and was well worth it my dewalt hammer drill works like new

Motor wouldn't run

Tool Type

Cordless Drill

Difficulty

Medium

Time

30-60 minutes

Tools Used

Screwdriver

2. Removed screws holding armature in place

3. Lifted out armature and magnet housing

4. Brushes mounted in frame slot - removed by hand

5. Reversed removal -

Make sure the new brushes are mounted in the frame; assure speed selector and magnetic housing ring are positioned to go together at same time after armature has been set, gear end of armature fits into gear housing.

Watch trigger wiring when installing brushes; could get pinched in fwd-reverse switch.

OEM stands for Original Equipment Manufacturer and means the part you’re buying is sourced directly from the manufacturer who made your product. At eReplacementParts, we sell only genuine OEM parts, guaranteeing the part you’re purchasing is of better design and of higher quality than aftermarket parts.

Our product descriptions are a combination of data sourced directly from the manufacturers who made your product as well as content researched and curated by our content & customer service teams. This content is edited and reviewed internally before being made public to customers.

Our customer service team are at the ready daily to answer your part and product questions. We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

All our part reviews are solicited directly from other customers who have purchased this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

Based on data from past customer purchasing behaviors, these parts are most commonly purchased together along with the part you are viewing. These parts may be necessary or helpful to replace to complete your current repair.

All our installation videos are created and produced in collaboration with our in-house repair technician, Mark Sodja, who has helped millions of eReplacementParts customers over the last 13 years repair their products. Mark has years of experience in selling and repairing both commercial and residential products with a specialty in gas-powered equipment.

This data is collected from customers who submitted a repair instruction after replacing this exact part. Customers can rate how easy the repair was to complete and how long it took. We aggregate this data to provide a repair rating that allows customers to quickly determine the difficulty and time needed to perform their own repair.