Why Read This Article?

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Article Breakdown

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

We explain the basics about band saw blades below, putting essential tool accessory information into the hands of shoppers.

Terms and Measurements

Each of the terms and measurements below has a key role in determining the particulars of band saw blade performance.

Even very minor changes can change a blade to suit it for cutting different materials, at different speeds, and so forth.

Gullet-

Just like other types of saw blades, gullets are those cutouts between teeth that allow material to be ejected when cutting.

Gullet Depth-

This is the length measured from the base of a gullet to the top of a cutting tooth.

Deeper gullets allow for faster cutting, because they can eject more material at a higher rate. Blades designed for slower cutting have shallower gullets, like with most metal cutting band saw blades.

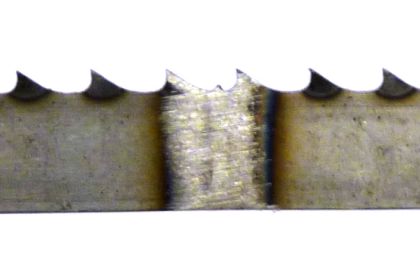

Weld-

Band saw blades have their ends welded together somewhere on the blade. The quality of this weld and its position between teeth greatly effects the durability and toughness of a blade.

Blade welds should be made at exactly the middle point between the tops of cutting teeth for the best strength.

Kerf-

This is the thickness of a blade's cutting teeth, and, therefore, also the thickness of the cut that a blade will make.

Kerf width will also partially determine the feed rate of a blade, as thicker kerf blades cut more slowly than thinner kerf blades.

Length-

The total length of a band saw blades is used to match their compatibility to specific saws.

Width-

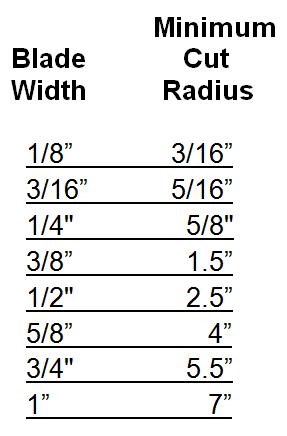

Width is the total length of the blade backing and the teeth, and it is also used to partially determine saw compatibility.

Blade width also effects the the type of contour cutting that can be done with a band saws. The wider a blade, the less maneuverability it has to make small-radius contour cuts.

This chart offers guidelines for matching band saw blade thickness to minimum radii of contour cuts:

For cutoff work, band saw blades should be as thick as the saw and material will allow.

TPI/Pitch-

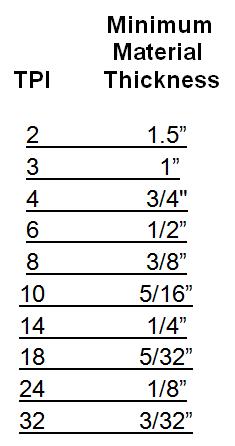

TPI stands for "teeth per inch" when talking about band saw blades. "Pitch" is interchangeable with TPI when talking about band saw blades.

Fewer teeth means more aggressive, faster cutting through materials that allow it, like most woods. More teeth per inch will make a blade cut more finely and slowly, and is better adapted for cutting very hard materials (like metals) that would wear out an aggressively-toothed blade prematurely.

TPI should also determine the thickness of material being cut, or vice versa. Band saw blades perform most optimally when at least three teeth are in the stock material at any given time. This means that blades have a minimum material thickness requirement for them to cut most efficiently, depending on the TPI.

Set-

"Set" refers to the combination of cutting tooth directions (the angles at which the cutting teeth are bent and/or angled as seen from a top view of the teeth), and the ordered arrangement of different cutting teeth types along the blade.

Rake Angle-

This is the angle at which the cutting face of band saw teeth are positioned to contact the target material. The more positive the rake angle, the more aggressive the cut.

[Back to top]

Blade Set Styles

Manufacturers achieve different effects by leaning band saw blade teeth away from the center line of the blade in various patterns.

Here we list a few of the most common set styles for band saw blades.

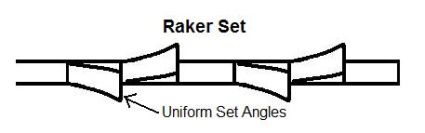

Raker Set

Tooth Pattern: Left, Right, Straight

Set Angles: Uniform

Raker blades are best for verticle resawing and contour cutting. They are also also adapted for horizontal cutoff work on thick metal.

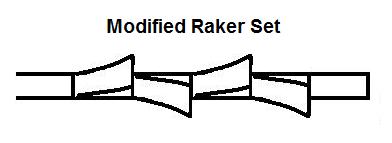

Modified Raker Set

Tooth Pattern: Left, Right, Left, Right, Straight

Set Angles: Uniform

This modification of the original raker makes these blades specialized for vertical wood cutting. Modified raker blades come in limited TPI and tooth type varieties.

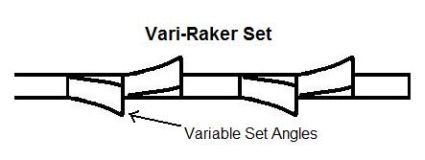

Vari-Raker Set

Tooth Pattern: Left, Right, Straight

Set Angles: Variable

Great "all around" woodworking blades.

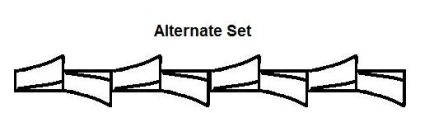

Alternate Set

Tooth Pattern: Left, Right

Set Angles: Uniform

Manufactured for fast, smooth woodworking cuts, and for work with non-ferrous metals.

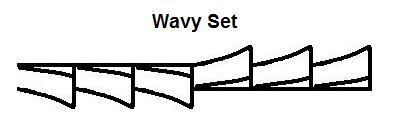

Wavy Set

Tooth Pattern: 3 Left, 3 Right

Set Angles: Controlled Angle Changes

This is the best set style for sawing thin materials and for doing interrupted cuts.

[Back to top]

Blade Tooth Types

In combination with the other blade features and measurements already discussed in this article, band saw cutting tooth types also weigh in heavily on a blade's function.

Differences in cutting tooth types mostly adjust blades to balance relative durability against sawing aggression for specific piecework materials.

Tooth types also help determine how fast these blades cut, how quickly they can eject chips, and even what shape those chips take when they're sawed out of the kerf.

Regular Tooth

[Back to top]

Blade Tooth Types

In combination with the other blade features and measurements already discussed in this article, band saw cutting tooth types also weigh in heavily on a blade's function.

Differences in cutting tooth types mostly adjust blades to balance relative durability against sawing aggression for specific piecework materials.

Tooth types also help determine how fast these blades cut, how quickly they can eject chips, and even what shape those chips take when they're sawed out of the kerf.

Regular Tooth

The most common cutting tooth type, because of its applicability for both cutoff and contour work on a wide range of materials.

Regular band saw blade teeth have flat cutting faces (zero degree rake angle), and deep gullets.

Hook Tooth

Hook teeth use a positive 10 degree rake angle to give blades extra aggression and a "digging" action that grabs the material, and they are generally spaced widely.

This tooth style is recommended for woods, non-ferrous alloys, and plastics, especially their harder varieties, and especially for longer cuts.

Band saw blades with a hook style teeth are most commonly available in raker set blades. Hook tooth gullets tend to curl chips as they are removed.

Skip Tooth

Skip tooth blade teeth are widely spaced like hook teeth, but their rake angle is zero degrees like regular teeth.

This tooth type is also characterized by a sharp angle where the teeth and gullets meet, and they tend to break chips up into smaller pieces.

Blades with this tooth type are designed for fast cutting through materials that would clog and gunk up a regular blade.

Variable Tooth

This tooth style varies tooth height, rake angle, and gullet depth. The lack of uniformity in this tooth design greatly reduces sawing vibration and noise.

This blade design is also great for all around shop work.

Modified Hook Tooth

When the aggression of a hook tooth's positive rake angle is needed for materials that also happen to clog blades up, modified hook teeth combine the best of hook tooth and skip tooth band saw cutting teeth designs.

The modification to the original hook tooth design on these blades is in the gullets, allowing them to clear material better than hook tooth blades.

[Back to top]

Band Saw Blade Materials

Like other friction-bearing power tool accessories, the materials that band saw blades are made from offer different levels of hardness and durability.

Carbon Steel-

The most traditional and least wear resistant of blade materials these days. However, carbon steel blades retain their place on the market, because inexpensive, general shop blades are still needed everywhere.

Bi-metal-

Becoming increasingly common, the tips of bi-metal blades are upgraded to high speed steel (HSS) for increased hardness, durability, and heat wear resistance.

Carbide Tipped-

The hardest, most durable, and most expensive. Carbide tipped blades can not be outperformed by other blade materials.

[Back to top]

Conclusion

Ready to put this article's information to the test? Visit our Band Saw Blades page and begin narrowing blade searches by the measurements and features discussed here.

Even simple items like blades, drill bits, and other accessories have a bit of a learning curve when it comes to making the right buy, and we think that shoppers and tool users should have the necessary information at their fingertips.

[Back to top]

What we're about.