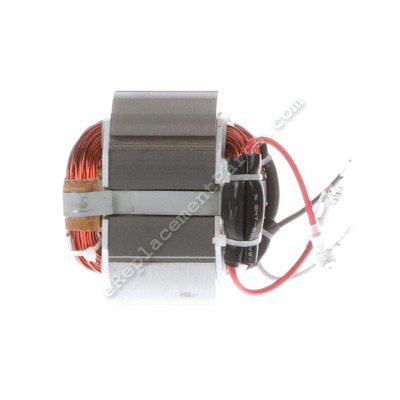

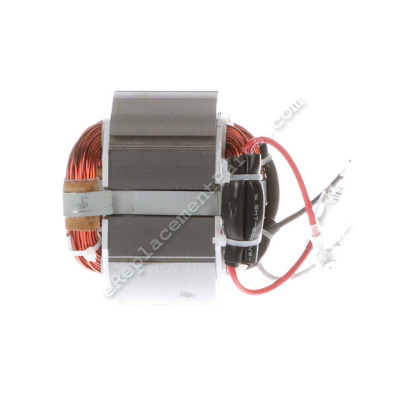

This is an original replacement field designed for use with Bosch table saws. In conjunction with armature it drives the unit. A field is usually damaged by overloading the power tool, or because of a bad armature. It is highly recommended to replace both carbon brushes when replacing a field. This item is sold individually. To complete this repair you would need a screwdriver.

• Make sure the saw is unplugged

• Remove brush covers and take out brushes

• Remove the cap and the housing screws

• Once the housing is removed you will have access to the field

• Disconnect all wires leading from the field

• Take out old field and replace it with a new one

• Re-connect all the wires

• Re-assemble the motor

Field 1619PA5590

OEM part for: Bosch

Part Number: 1619PA5590

Jump To:

Product Description ?

- 120V

- Classification: Part

- Weight: 3.00 lbs.

- Shipping: Ships Worldwide

Frequently Purchased Together ?

Compatibility

This part will fit the following 10 machines

Bosch

This item works with the following types of products:

- Saw Parts

- Table Saw Parts

This part replaces obsolete part #: 2610996867

Repair Videos ?

|

This article defines the basic parts of most power tools, explains how they work, and what to look for when they stop wo...

September 25, 2009

|

Customer Part Reviews ?

- 1

Questions & Answers ?

Our customer Service team is at the ready daily to answer your part and product questions.

Ask our Team

We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

Does this fit my product?Questions & Answers for Field

Customer Repair Instructions ?

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part.

Motor lost power and then ran slowly in reverse.

Tool Type

Table Saw

Difficulty

Medium

Time

1-2 hours

Tools Used

Screwdriver, Pliers, Socket set

Parts Used

Next I ordered the field and a set of brushes. The armature looked fine but I still sanded it down and cleaned the slots between the bars w/ a brass wire "tooth" brush. The field was a very tight fit and difficult to pull from the plastic motor housing. And then, even harder to press back in and have the mounting holes be orientated correctly for the screws that went thru them. I finally took some 150 grit sand paper to the12 support fins in the plastic case and shaved them down just enough so the field would slide into its home a little more easily. All is well now. For $115, I have a mostly new table saw motor, which works like it used to. A local repair shop wanted 3 or 4 times that for parts and labor. Glad I tried to fix it myself.

Table saw blade was running backwards

Tool Type

Table Saw

Difficulty

Hard

Time

More than 2 hours

Tools Used

Screwdriver, Wire Crimps, Channel Locks

Parts Used

Motor bearings worn out

Tool Type

Table Saw

Difficulty

Medium

Time

1-2 hours

Tools Used

Screwdriver, Socket set, Wrench Set, Nutdriver, Wire strippers/crimper

2.) Turned table saw upside down and removed plastic table support frame from cast table to access motor (4 allen-head cap screws & 2 small bolts).

3.) Removed brushes (2)

4.) Removed motor end cap (3 screws) to expose rear motor bearing and wiring to motor field

5.) Removed motor housing from cast gear box/blade support (4 screws). Armature remained in gear box.

6.) Removed armature by pulling out of gear box and front bearing

7.) Removed front bearing retainer (2 screws) and removed bearing with inside puller. Replaced with new bearing and re-attached retainer.

8.) Removed rear bearing by cutting off with dremel and cutting wheel. The outer bearing had fallen off with ball bearings so only inner race remained on armature shaft and nothing for puller to grab to...so had to cut off.

9.) Replaced new bearing on shaft and cleaned armature with damp rag and a little brake cleaner.

10.) Removed wire nut caps from field wiring and rear motor cap (which contains speed control board). Removed 2 bolts that held field in motor housing. Removed field from motor housing by tapping out from rear.

11.) Replace with new field. Reattached wire nuts and tightened 2 bolts.

12.) Added grease to armature shaft gear end and reinstalled cast gear housing/blade support.

13.) Reassembled saw in reverse order

14.) Replaced saw blade

15.) Plugged in and ran like new. Parts for $100 saved my $600 table saw. Tool retailers wanted $300 minimum to begin repair which would be used towards the final repair bill. Glad I did it myself, but you should have some mechanical and electric motor knowledge and able to keep parts in order during disassembly.

Saw ran at real slow rpm , no way it would cut anything

Tool Type

Table Saw

Difficulty

Medium

Time

More than 2 hours

Tools Used

Screwdriver, Pliers, Nutdriver

Loud noise, not sure which part fixed it, but didn't want to put it together twice

Tool Type

Table Saw

Difficulty

Medium

Time

30-60 minutes

Tools Used

Pliers, Nutdriver, Bering puller

Parts Used

Table saw lost power and sparks were coming out of the motor

Tool Type

Table Saw

Difficulty

Medium

Time

1-2 hours

Tools Used

Screwdriver, Pliers, Socket set

field became loose, and moved into fan blade on armature, cut field windings. i believe it was missing 2 screws from the factory

Tool Type

Table Saw

Difficulty

Medium

Time

30-60 minutes

Tools Used

Screwdriver, wire crimper

Parts Used

Table not working

Tool Type

Table Saw

Difficulty

Medium

Time

15-30 minutes

Tools Used

Screwdriver, Pliers

Parts Used

OEM stands for Original Equipment Manufacturer and means the part you’re buying is sourced directly from the manufacturer who made your product. At eReplacementParts, we sell only genuine OEM parts, guaranteeing the part you’re purchasing is of better design and of higher quality than aftermarket parts.

Our product descriptions are a combination of data sourced directly from the manufacturers who made your product as well as content researched and curated by our content & customer service teams. This content is edited and reviewed internally before being made public to customers.

Our customer service team are at the ready daily to answer your part and product questions. We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

All our part reviews are solicited directly from other customers who have purchased this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

Based on data from past customer purchasing behaviors, these parts are most commonly purchased together along with the part you are viewing. These parts may be necessary or helpful to replace to complete your current repair.

All our installation videos are created and produced in collaboration with our in-house repair technician, Mark Sodja, who has helped millions of eReplacementParts customers over the last 13 years repair their products. Mark has years of experience in selling and repairing both commercial and residential products with a specialty in gas-powered equipment.

This data is collected from customers who submitted a repair instruction after replacing this exact part. Customers can rate how easy the repair was to complete and how long it took. We aggregate this data to provide a repair rating that allows customers to quickly determine the difficulty and time needed to perform their own repair.