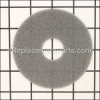

This authentic replacement part is designed for use with Craftsman snowblowers. Ball bearings are used to reduce friction between rotating parts. The balls or rollers take the load and spin, distributing the weight evenly while the minimal contact area of the ball reduces friction. This bearing helps to secure the arbor shaft, allowing it to rotate. Bearings experience constant wear from pressure, heat, vibration, and friction eventually requiring replacements. This high-quality component is made of durable metal and is sold individually. A wrench set will be needed to perform this repair.

Bearing, Ball 11/16x1 1705897SM

OEM part for: Murray, Briggs and Stratton, Craftsman, Snapper, Simplicity

Part Number: 1705897SM

Jump To:

Frequently Purchased Together ?

Compatibility

This part will fit the following 2334 machines

Murray

Craftsman

Snapper

Simplicity

This item works with the following types of products:

- Lawn Tractor Parts

- Snowblower Parts

- Lawn Mower Parts

- Engine Parts

- Vacuum Parts

- Freezer Parts

This part replaces obsolete part #: 43846, 43846MA, MT1501389MA, 49562MA, 724001, 1722703, 7013020, 726957, 7026808, 1705897, 1501389MA, 1001196MA

Customer Part Reviews ?

- 1

Questions & Answers ?

Our customer Service team is at the ready daily to answer your part and product questions.

Ask our Team

We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

Does this fit my product?Questions & Answers for Bearing, Ball 11/16x1

Customer Repair Instructions ?

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part.

Major bearing failure of blade shaft.

Tool Type

Lawn Mower

Difficulty

Medium

Time

1-2 hours

Tools Used

Socket set, Wrench Set, Adjustable Wrench, Arbor press

Parts Used

- Bearing, Ball 11/16x1 - 1705897SM

- Wheel&tire Asmy Hunte - 1729708SM

- Foam Gasket - 1707335SM

- Cover, Arbor Housing - 1713199ASM

- Washer, Cupped - 1713619SM

- Shield, Grass, Lower - 1713196SM

- Shaft, Arbor - 1713612SM

- Pulley - 1732951SM

- Housing Assembly, Arbor Bottom - 1713338ASM

- Hub - 1713616SM

- Spacer - 1732543SM

Note: When pressing the bearings into the housings, it is critical to apply force only to the outer race of the bearings.

Bad bearings

Tool Type

Lawn Mower

Difficulty

Hard

Time

1-2 hours

Tools Used

Socket set, impact and grinder

Bearing failure

Tool Type

Snowblower

Difficulty

Medium

Time

More than 2 hours

Tools Used

Screwdriver, Pliers, Power Drill, Socket set, Wrench Set

Parts Used

Impeller shaft tension roll pins needed replaced

Tool Type

Snowblower

Difficulty

Medium

Time

More than 2 hours

Tools Used

Screwdriver, Power Drill, Socket set, Wrench Set, Nutdriver, Adjustable Wrench

remove auger drives from shroud by removing auger drive pulley from impeller shaft

remove broken tension roll pins and replace with new

reassemble auger assembly (installed new impeller bearing, key, bearing housing)

replaced auger drive belt while access was readily available

reattached auger assembly/shroud to engine

old craftsman zero-turn mower .Cant buy a complete spindle but got all parts to rebuild it on order site .

Tool Type

Lawn Mower

Difficulty

Medium

Time

30-60 minutes

Tools Used

Socket set, Wrench Set

Bearings wore out on blade arbor

Tool Type

Lawn Mower

Difficulty

Medium

Time

1-2 hours

Tools Used

Pliers, Socket set, Wrench Set, air tools

2- Disassembled deck arbors

3- Replaced bearings, spacers and arbors

4- Replaced deck

Bearing failure on main drive shaft.

Tool Type

Snowblower

Difficulty

Medium

Time

More than 2 hours

Tools Used

Screwdriver, Socket set, Wrench Set

Bearing froze and scored the arbor shaft. Also hub pulley keys sheared.

Tool Type

Lawn Tractor

Difficulty

Medium

Time

30-60 minutes

Tools Used

Socket set, Wrench Set, Adjustable Wrench, grease gun

2. Took mower deck main drive apart and remembered location.

3. Purchased all new parts and spares.

4. Used online diagram to assemble the new parts and installed the arbor shaft.

5. Greased the shaft.

6. Installed V belts and checked for free rotation.

7. Installed deck on tractor and V belt to engine

8. Test run the tractor and mower deck.

9. Checked all fasteners to make sure tight.

10. Cut my and my neighbors lawn, about 4 acres.

Bearings worn down to sleeves and blades needed replacement.

Tool Type

Lawn Tractor

Difficulty

Hard

Time

More than 2 hours

Tools Used

Screwdriver, Socket set, Wrench Set, Adjustable Wrench, Hammer, cold chizel, punch, vice

Took old blades off.

Removed assembly where blades were attached with sockets and wrenches.

Used a vice to hold each assembly to free large nut end.

Pulled apart the assembly to reveal the worn bushings - ball bearings were in grease.

Used a hammer and cold chisel to separate inside worn bushing from the shaft.

Used a hammer and punch to separate the outside worn bushing from the shaft.

Removed old foam gasket and installed new one after tapping in the new bearing.

Repeated process for second blade assembly.

Attached both blade assemblies to mower attachment.

Attached blades and put attachment back on and put the belt back on.

Started mowing.

OEM stands for Original Equipment Manufacturer and means the part you’re buying is sourced directly from the manufacturer who made your product. At eReplacementParts, we sell only genuine OEM parts, guaranteeing the part you’re purchasing is of better design and of higher quality than aftermarket parts.

Our product descriptions are a combination of data sourced directly from the manufacturers who made your product as well as content researched and curated by our content & customer service teams. This content is edited and reviewed internally before being made public to customers.

Our customer service team are at the ready daily to answer your part and product questions. We have a dedicated staff with decades of collective experience in helping customers just like you purchase parts to repair their products.

All our part reviews are solicited directly from other customers who have purchased this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

All our customer repair instructions are solicited directly from other customers just like you who have purchased and replaced this exact part. While we moderate these reviews for profanity, offensive language or personally identifiable information, these reviews are posted exactly as submitted and no alterations are made by our team.

Based on data from past customer purchasing behaviors, these parts are most commonly purchased together along with the part you are viewing. These parts may be necessary or helpful to replace to complete your current repair.

All our installation videos are created and produced in collaboration with our in-house repair technician, Mark Sodja, who has helped millions of eReplacementParts customers over the last 13 years repair their products. Mark has years of experience in selling and repairing both commercial and residential products with a specialty in gas-powered equipment.

This data is collected from customers who submitted a repair instruction after replacing this exact part. Customers can rate how easy the repair was to complete and how long it took. We aggregate this data to provide a repair rating that allows customers to quickly determine the difficulty and time needed to perform their own repair.