Why Read This Article?

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Article Breakdown

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

"Cam-out" is what happens when the rotational force of a screwdriver bit causes it to disengage the fastener and slip out. Some drive systems will cam-out at lower torques, others at higher torques. A drive system's tendency to cam-out also affects how quickly or not the bit will wear.

A lot can be understood about a screwdriver bit drive system just by looking at the shape of its point. Designs with more contact points to the fastener distribute pressure more evenly, have more driving power due to increased contact area, can handle more torque before camming-out, will cam-out less, and will wear more slowly by consequence.

"Cam-out" is what happens when the rotational force of a screwdriver bit causes it to disengage the fastener and slip out. Some drive systems will cam-out at lower torques, others at higher torques. A drive system's tendency to cam-out also affects how quickly or not the bit will wear.

A lot can be understood about a screwdriver bit drive system just by looking at the shape of its point. Designs with more contact points to the fastener distribute pressure more evenly, have more driving power due to increased contact area, can handle more torque before camming-out, will cam-out less, and will wear more slowly by consequence.

Before discussing the different drive systems available on the market, shoppers can tackle a much simpler decision between insert bits and power bits as discussed below.

Before discussing the different drive systems available on the market, shoppers can tackle a much simpler decision between insert bits and power bits as discussed below.

Screwdriver Bit Buying Guide Chart

|

|

Low-Med Torque

|

Med-High Torque

|

|

DeWalt

|

||

|

Bosch

|

||

|

Hitachi

|

||

|

Makita

|

||

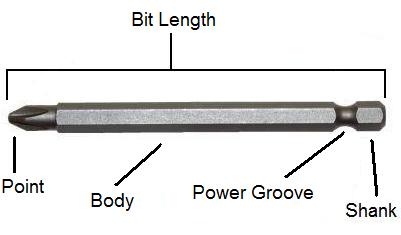

Although they are often installed directly into jaw chucks by users, insert bits were originally designed to fit in the ends of extension adapters.

The snap ring notch on the bodies of insert bits helps them hold firmly in bit holders.

- Because of their low cost, insert bits are an especially good choice for drive systems that tend to wear bits down through frequent cam-out, or any application where bits are expected to wear through frequent, heavy use.

Power Bits Because power bits are generally more expensive than insert bits, they're usually bought to last longer than insert bits.

A power bit's power groove is shaped for use in quick change adapters and chucks. Quick change chucks are increasingly popular and standard to many impact drivers/wrenches. Metal balls inside a quick change chuck engage a power bit's power groove when the bit is installed.

A power bit's power groove is shaped for use in quick change adapters and chucks. Quick change chucks are increasingly popular and standard to many impact drivers/wrenches. Metal balls inside a quick change chuck engage a power bit's power groove when the bit is installed.

- To extend the life of power bits, it's best for shoppers to buy high quality bits made from wear-resistant materials.

The "slot" or "slotted" drive system is one of the oldest fastening systems, and it is the most simple. Cam-out is much more likely with drive systems that have fewer points of contact between the bit and the fastener, like the slot system. With the fewest points of contact of any system, slot bits cam-out at very low torque.

Also, it is hard to find slotted fasteners and bits that match exactly between brands, because of the wide-spread, more-or-less unstandardized manufacture of slotted tools and fasteners. This is especially true of their width measurement on the driving face, as most manufacturers do not list this measurement with bit length and other specifications.

Pros:

Also, it is hard to find slotted fasteners and bits that match exactly between brands, because of the wide-spread, more-or-less unstandardized manufacture of slotted tools and fasteners. This is especially true of their width measurement on the driving face, as most manufacturers do not list this measurement with bit length and other specifications.

Pros:

- Their shape makes slot fasteners easy to turn with common objects.

- Bits can be re-ground.

- Slots can be recut easily.

- Drivers of different sizes can be used to turn fasteners.

- Bits decenter easily.

- Only two available positions (at 180° to each other) for bits to engage fasteners.

- Low torque cam-out.

- Increased cam-out with slot bits and fasteners increases their wear rate.

- Tightly fitting bits and fasteners can be difficult to find between brands.

Phillips Bits

The Phillips drive system improves upon the slot system in many ways. First, the cross design greatly increases the driver's contact area with the fasteners, allowing more positions for bits to engage fasteners, and increasing the overall grip of the bit.

Phillips bits have rounded corners at their cross sections and blunted tips which are designed (intentionally) to allow the bit to cam-out at a specific torque range to prevent over-tightening. Although their tendency to cam-out increases wear to bits and fasteners, they cam-out much less easily than slot systems and reduce the risk of damaging the material being worked on as they prevent over-tightening.

Since their introduction in the 1930's, improvements in power tools that allow users to set tools at fixed torque have encouraged production of new drive systems that reduce cam-out even further.

Phillips bits are sized by simple, round numbers, such #1, #2, #3, etc.

Phillips bits have rounded corners at their cross sections and blunted tips which are designed (intentionally) to allow the bit to cam-out at a specific torque range to prevent over-tightening. Although their tendency to cam-out increases wear to bits and fasteners, they cam-out much less easily than slot systems and reduce the risk of damaging the material being worked on as they prevent over-tightening.

Since their introduction in the 1930's, improvements in power tools that allow users to set tools at fixed torque have encouraged production of new drive systems that reduce cam-out even further.

Phillips bits are sized by simple, round numbers, such #1, #2, #3, etc.

Pros:

- Prevents over-tightening by allowing for cam-out.

- Can withstand more torque than slot drive systems before camming-out.

- Extremely common.

- Drivers of different sizes can be used to turn fasteners.

- Frequent cam-out causes wear.

- Not usable at high torques.

- Easily confused with less-common "cross" and "Frearson" driving systems.

Pozidriv Bits

The Phillips company improved upon their Phillips drive system by developing Pozidriv bits and fasteners.

This drive system increases driving surface by including an additional cross section (at 45° angles) withing the large cross. These additional grooves can be seen on the bit pictures below, which are represented on the tops of fasteners by four additional lines on their heads.

Pozidriv bits can operate at higher torque than Phillips systems before camming-out. Phillips heads bits can be used to turn Pozidrive fasteners (although not optimally), but Pozidriv bits will ruin Phillips fasteners if mixed up.

Like Phillips bits, Pozidriv bits are sized by round numbers, but they expressed as PZ0, PZ1, PZ2, PZ3, etc. It's best to match Pozidriv bit sizes exactly to fastener sizes to maximize the benefits of their design.

Pozidriv bits can operate at higher torque than Phillips systems before camming-out. Phillips heads bits can be used to turn Pozidrive fasteners (although not optimally), but Pozidriv bits will ruin Phillips fasteners if mixed up.

Like Phillips bits, Pozidriv bits are sized by round numbers, but they expressed as PZ0, PZ1, PZ2, PZ3, etc. It's best to match Pozidriv bit sizes exactly to fastener sizes to maximize the benefits of their design.

Pros:

- Greatly reduced cam-out, and usable at higher torque.

- Reduced wear to bits and fasteners.

- Fasteners can be turned with more common Phillips bits.

- Easily confused with Phillips bits and fasteners.

- Pozidriv bits can damage Phillips fasteners if mixed up.

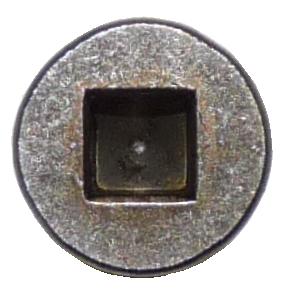

Square Bits

Square bits are often called "square recessed" bits (because of their tapered, "recessed" nose) and "Robertson" bits (for the name of their first developer).

With such a different approach to driving system design, square bits offer unique advantages and are increasingly appreciated by tool users.

Square bit design offers high torques, low cam-out performance, are easily used one-handed, and are self-centering.

Square bit design offers high torques, low cam-out performance, are easily used one-handed, and are self-centering.

Square bit sizes are designated by found numbers, expressed as S0, S1, S2, S3, etc. Square bit sizes must match exactly to fastener sizes.

Pros:

- High torque, low cam-out.

- One-handed use because of tight fit.

- Easily removed when painted over.

- Self-centering.

- Not as widely used as other drive systems.

- Can over-tighten without torque-limiting tool settings.

- Bit sizes must match exactly to fastener sizes.

Hex Bits

Hex drive systems are very old, and their bits are commonly called "Allen" wrenches or keys.

Although old, their six sided shape gives them great usability and makes them inexpensive to manufacture. They are still commonly used in machinery fastening.

Hex bits are sized by their diameter measurements in either the English standard or metric systems. Hex bit sizes should match fastener sizes exactly.

Although old, their six sided shape gives them great usability and makes them inexpensive to manufacture. They are still commonly used in machinery fastening.

Hex bits are sized by their diameter measurements in either the English standard or metric systems. Hex bit sizes should match fastener sizes exactly.

Pros:

- Widely used.

- Shape allow high torque fastening without cam-out.

- Inexpensive to manufacture.

- Not as specialized as other drive systems.

- Fastener and bit sizes must match.

Torx Bits

Torx was originally developed as a tamper-resistant fastening system for electronics and automobiles, but they have become very popular for their advantages. Torx's six point, "hexalobular" shape increases their driving area and applies the rotational force of the drill more evenly.

Their several access positions and low cam-out make torx bits fast, efficient, and wear resistant. Also, it's less expensive to buy a complete torx bit set as compared to other systems, because of their relatively fewer size increments.

Their several access positions and low cam-out make torx bits fast, efficient, and wear resistant. Also, it's less expensive to buy a complete torx bit set as compared to other systems, because of their relatively fewer size increments.

Several variations on the torx bit are available, such as tamper-proof designs that include a pin in the center of fasteners.

Torx bits are sized with round numbers (often increments of 5), and expressed T10, T15, T20, etc. Because of their complicated shape, hex bit sizes must match fastener sizes exactly.

Pros:

- High torque, low cam-out. Especially good with torque-setting tools.

- Low wear.

- Shape allows, fast, easy use.

- Convenience of fewer overall sizes.

- Most common high-torque fastener

- Not appropriate where over-tightening is a concern.

- Not turn-able with any other system.

- Bit and fastener sizes must match exactly.

Conclusion Shoppers can find the screwdriver bits they need fast on eReplacementParts.com's Screwdriver Bits page. Just click the drive system you're looking for, and the page will refresh with matching results. By thinking about cam-out and the level of torque they need from a screwdriver bit, shoppers can choose the system that conserves bit wear (and therefore, expense) the best. Take a look at our other Power Tool Accessories here at our online warehouse. [Back to top]

What we're about.