Why Read This Article?

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Article Breakdown

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Hole saw mandrels are the intermediate pieces of hole saw drill bit assemblies that connect hole saws to drill chucks. If you're looking to find a mandrel that matches your hole saws or power drill, the information below is everything you need to know to get the right mandrel. Understanding the parts of hole saw mandrels, the various compatibility measurements available on the market, and how those measurements relate to your tool and hole saw can make you an expert shopper.

Hole Saw Mandrel Buying Guide Chart

|

|

Thread Sizes

|

|

|

Chuck Size

|

1/2"-20

|

5/8"-18

|

|

1/4"

|

X

|

|

|

3/8"

|

||

|

1/2"

|

||

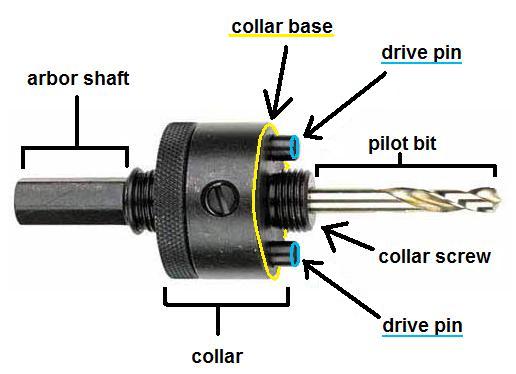

Directly from the drill chuck, a hole saw mandrel's arbor shaft (shank) extends to its collar. The base of the mandrel collar has a threaded collar screw protruding from its center that ends in a drill bit (most often a pilot bit, for starting the hole).

Hole saws are affixed to the base of the mandrel by passing the mandrel drill bit through a center hole in the hole saw. The hole saw is then screwed onto the mandrel collar base screw. Most hole saw mandrels (but not all) also have strategically positioned drive pins that match corresponding holes in the bases of hole saws, on the outside of their center holes. The pins help to stabilize the saw.

Major parts of a hole saw mandrel:

- arbor shaft (shank)- affixes to drill chuck.

- collar- the middle section of the mandrel.

- collar base- the part of the collar on which the hole saw attaches.

- collar screw- positioned at the center of the collar base.

- drill bit- protrudes from the collar screw.

- drive pins- attach to corresponding holes in hole saws.

1. The arbor shaft size (diameter) and the drill chuck size must match.

2. The collar screw thread size and the hole saw thread size must match.

[Back to top]

Manufacturer Compatibility Systems

Many manufacturers of hole saws and their mandrels develop their own compatibility naming systems to simplify shopping. There's nothing wrong with using manufacturer compatibility systems if there's a certain brand name of mandrel and hole saw that you like, but it never hurts to know the specifics too.

Although these systems can be convenient and work very well when buying mandrels and hole saws from the same manufacturer, getting a replacement mandrel for your hole saw from the same manufacturer isn't always an option.

This is where knowing specific measurements and how they relate to compatibility comes in handy. In addition, many manufacturers use the actual measurements instead of a unique compatibility naming system.

In any case, it's best to understand the measurement specifics discussed below when shopping for hole saw mandrels.

[Back to top]

Match the Hole Saw Mandrel Shank to the Chuck

The first compatibility feature to match is the hole saw mandrel shank size (diameter) to the drill chuck size. Most hole saw mandrel arbors are designed to fit "jaw type" drill chucks, and the measurements in this section refer only to jaw type drill chucks.

Some hole saw mandrels are made for SDS chuck systems, in which case, the measurements here do not apply.

Chuck Sizes

Jaw type drill chucks come in three sizes:

- 1/4" (less common)

- 3/8"

- 1/2"

The chuck size partially reflects the power of the drill as well. For hole saws, drills with larger chucks can accept larger hole saws, and, generally, will be increasingly powerful to handle the workload of the larger saws.

The chuck size partially reflects the power of the drill as well. For hole saws, drills with larger chucks can accept larger hole saws, and, generally, will be increasingly powerful to handle the workload of the larger saws.

Because of the way that jaw type chucks work (by closing around installed bits), larger chucks can also accept bits and adapters of smaller diameters. Drill chucks cannot accept bits and adapters with shanks larger than their chuck size.

[Back to top]

Hole Saw Arbor Shaft Diameter

Hole saw arbor shafts come in three diameter sizes:

- 1/4"

- 11/32"

- 7/16"

This means that some manufacturers will use 11/32" and 3/8" interchangeably when identifying mandrel specifications, even though the actual diameter is 11/32". [Back to top] Arbor Shaft to Chuck Size Compatibility

The three mandrel arbor diameter sizes correspond directly to the three drill chuck sizes. The charts below show which drill chuck sizes can accept the three mandrel arbor shaft diameter sizes, and the reverse, which arbor diameter sizes can be accepted by the three drill chuck sizes.

Mandrel Arbor Diameter Compatible Drill Chuck Size(s)

1/4" (arbor diameter) → 1/4", 3/8", and 1/2" (chucks)

11/32" (arbor diameter) → 3/8", and 1/2" (chucks)

7/16" (arbor diameter) → 1/2" (chucks only)

Drill Chuck Size Compatible Mandrel Arbor Diameter(s) 1/4" (chuck) → 1/4" (arbor diameters only)

3/8" (chuck) → 1/4", and 11/32" (arbor diameters)

1/2" (chuck) → 1/4", 11/32", and 7/16" (arbor diameters)

As chuck size decreases, a chuck's compatibility options for hole saw mandrel arbor shaft sizes decreases as well. Despite a chuck's ability to hold an arbor shaft of a smaller diameter, it's always best to match the arbor shaft size closer to the chuck size whenever possible.

[Back to top] Shank Styles

Hole saw mandrel arbor shafts are available in four major styles:

- round

- flats

- hex

- SDS

This is the second compatibility item that must be matched when shopping for a hole saw mandrel. Hole saws affix to mandrels by screwing onto a mandrel's threaded collar screw in the center of the collar base. This means that both the center hole of the hole saw and the mandrel's collar screw are threaded to specific sizes and must match exactly.

Luckily, there are only two major hole saw mandrel thread sizes:

- 1/2"-20 thread size, and

- 5/8"-18 thread size

Generally speaking, 5/8"-18 thread hole saws can capacitate hole saw of larger diamter, and because hole saw thread size corresponds to mandrel thread size, the thread size of a hole saw mandrel collar screw determines the range of hole saw diameter sizes that are compatible with the mandrel.

In addition, hole saw mandrels with a 1/4" arbor shaft diameter are only available in 1/2"-20 thread sizes, meaning that, in the case of 1/4" diameter mandrels, the arbor diameter determines the thread size, which in turn determines (and restricts) the range of hole saw diameter sizes that are compatible with the mandrel.

The chart below shows which thread sizes are available for the three different mandrel arbor diameter sizes:

Mandrel Arbor Diameter Thread Size Availability

1/4" → 1/2"-20 only

11/32" → 1/2"-20 and 5/8"-18

7/16" → 1/2"-20 and 5/8"-18

So, each of the two thread sizes corresponds to a given range of compatible hole saw diameter sizes. Smaller hole saws for mandrels with 1/2"-20 thread sizes, and larger hole saws for mandrels with 5/8"-18 thread sizes, generally.

We say "generally," because there's quite a bit of variation in this range of compatible hole saw diameter sizes (dictated by mandrel thread size) among manufactures.

Despite this variation, we offer the chart below to show what two plausible hole saw diameter compatibility ranges might look like in relation to a mandrel's thread size:

Mandrel Thread Size Hole Saw Diameter Compatibility Range

1/2" - 20 → 9/16" to 1 & 3/16"

5/8" - 18 → 1 & 1/4" to 8 & 9/16" Here are three guidelines to make choosing hole saw mandrel thread size easier:

1. If you already have the hole saw you need, great! Figure out its thread size and find a mandrel with the matching thread size.

2. If you're not shopping to match a mandrel to a specific hole saw, keep the approximate sizes of the holes you want to drill in mind when selecting mandrel thread size.

(Or, if the drill's chuck size will allow it, you can just buy two or more mandrels for your drill and be ready for any size of hole saw.)

3. Remember that hole saw mandrels only come in 1/2"-20 thread size for 1/4" arbor diameter mandrels.

This means you will only be able to use hole saws sizes compatible to 1/2"-20 thread size mandrels if your drill has a 1/4" chuck size.

[Back to top]

Select Additional Hole Saw Mandrel Features

Like other power tool accessories, hole saw mandrels are often designed with special features that either improve performance or meet special application needs.

Here's a list of some of a few mandrel accessories and features that shoppers can consider in addition to compatibility measurements:

mandrel extensions- long mandrel arbor extensions are often sold separately to lengthen the reach of hole saws.

locking mandrels- many manufacturers have developed mandrels with additional locking mechanisms that stabilize the hole saw.

quick change mandrels- some mandrels are specifically designed for fast changing between hole saws.

correction mandrels- specialized mandrel designs are available that guide the re-drilling of an existing hole (a mistake) to a larger diameter.

[Back to top]

Conclusion

Visit our Hole Saw Mandrels page here at eReplacementParts.com to browse our inventory of arbors from major manufacturers like DeWALT and Milwaukee.

Use this article's information to narrow down your search by compatibility measurements.

We make this and other information tools available on our website so that tool users can save time when it comes to keeping their equipment running, letting them focus on their projects instead.

[Back to top]

What we're about.