Why Read This Article?

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

Article Breakdown

Finish Nailer Repair - Replacing the Driver Guide (Ridgid Part # 79004001022)

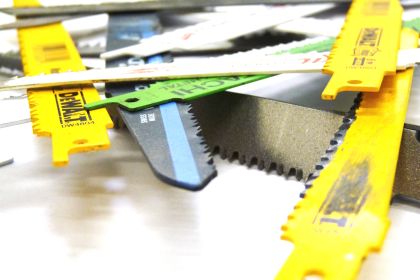

Some of the similarities that recip blades share with other blades are the materials they're made with and the kinds of set styles available for them (raker, wavy, etc.). However, little details (like measurements and dimensions) are important for recip saw blades for different reasons.

Some of the similarities that recip blades share with other blades are the materials they're made with and the kinds of set styles available for them (raker, wavy, etc.). However, little details (like measurements and dimensions) are important for recip saw blades for different reasons.

We describe the ins and outs of reciprocating saw features and manufacturing differences below, so that shoppers will have everything they need to find blades that best match their application.

Measurements and Dimensions

Although recip blades share some common measurements with other saw blade types, many of the measurements for recip blades are important for completely different reasons.

Below is a list of the most important reciprocating saw blade dimensions and measurements to consider when making a purchase. Length, width, and thickness have a lot to do with determining blade performance, so they should weigh in heavily.

TPI-

Teeth Per Inch (pitch) has a lot to do with how aggressive or not a blade is. Fewer teeth per inch generally means faster, rougher cuts.

Blades with more teeth per inch are generally slower and finer cutting, but this is usually not a problem, because low TPI blades are usually made for metal cutting that is generally done best at slower speeds.

TPI choice in a blade should also be partially determined by the thickness of material being cut. The general guideline is that at least three cutting teeth should be in the material at all times.

Most recip blades are available in the 6-36 TPI range, but most general wood and metal cutting is done by blades in the 6-18 TPI range. Blades with a TPI higher than 18 are often for specialty applications, or strictly for metal cutting.

length-

This measurement greatly affects the performance of reciprocating saw blades. Depending on the application, recip blades need to be more or less flexible and more or less tough, like for cutting through wood with nails.

Longer recip blades allow more flexibility, and are a little less aggressive than shorter blades. Shorter reciprocating saw blades will be stiffer and more aggressive, because of their rigidity.

Also, users of recip blades should overshoot their blade length just a little. This is because reciprocating saws operate best when some of the blade is left to protrude from the work.

The general rule is that reciprocating saw blades should be one or two inches longer than the work they're cutting through, reducing the chance of slipping and binding in the work.

width-

Wider recip blades are a little more aggressive, and the extra support helps make them better suited for nails in wood cutting.

Lower width blades are best for finer cutting, and applications that need some additional flexibility.

thickness-

Like other saw blade types, the thickness of the blade does more than just determine the kerf width of the cut. This is also true for reciprocating saw blades.

Thinner blades tend to cut faster and are more flexible than thicker blades. Thicker recip saw blades are better for heavier applications, and for cutting through nails when necessary.

Most reciprocating saw blades are available between 0.035 inches and 0.062 inches in thickness.

[Back to top]

Tooth Set Styles

Recip saw blade set styles are virtually the same as set styles for other blades, like bandsaw and jigsaw blades, and similar application guidelines apply.

We've listed the most common and important recip blade tooth designs and sets below.

We've listed the most common and important recip blade tooth designs and sets below.

Wavy Set

Wavy set recip saw blades are great for very straight cuts, all around wood sawing, and they are very wear-resistant.

Wavy set blades are usable on all kinds of wood, plywood, plastic, and metals

Wavy Set Pattern (viewed from above)

![]() [Back to top]

Raker Set

[Back to top]

Raker Set

Fast cutting, and all-purpose, raker set reciprocating saw blades alternate cutting teeth left to right in a "side set" style (extending over the thickness of the blade body).

Raker blades are generally more aggressive and faster cutting that wavy set blades, and perform better for contour sawing.

Raker Set Pattern (viewed from above)

![]() [Back to top]

Variable Pitch

[Back to top]

Variable Pitch

"Pitch" is another way of saying TPI, a way of describing the density of cutting teeth along the length of the blade.

Variable pitch is not another kind of set style, but a feature that can be combined with existing set styles. The number of teeth per inch on a variable pitch reciprocating saw blade will be different on different parts of the blade.

Varying the pitch/TPI like this makes the blades more all-purpose, helps them to cut faster with better material removal, and reduces the risk of the blades catching or snagging while in operation.

[Back to top]

Reciprocating Saw Blade Materials

The four materials listed below are the most common materials used to make reciprocating saw blades, and they increase in hardness going down the list.

Although a harder blade cutting tooth material always means a more durable blade, harder materials are not always best for every application, mostly because certain applications need the flexibility that less durable materials offer.

Again, choosing this feature is a matter of application matching, because the tougher, expensive, more durable blades aren't always the best choice.

Although a harder blade cutting tooth material always means a more durable blade, harder materials are not always best for every application, mostly because certain applications need the flexibility that less durable materials offer.

Again, choosing this feature is a matter of application matching, because the tougher, expensive, more durable blades aren't always the best choice.

High Carbon Steel (HCS)-

This is the most flexible of the recip saw blade materials, but it is also the least durable. Because of their softness, high carbon steel blades are best when used only on woods, particle board, and plastics.

However, their flexibility is necessary for many kinds of cutting, and, being the most inexpensive blades, they are often the most economic choice.

High Speed Steel (HSS)-

A steel tempering process makes these blades more resistant to heat, and more durable than carbon steel blades. This extra hardness and protection makes them usable for many kinds of metal cutting without excessive wear.

Bi-Metal (BIM)-

Bi-Metal saw blades combine the best of high carbon steel and high speed steel. The body of these blades is made of high carbon steel (for the flexibility it offers), and the teeth are made with high speed steel (for the hardness/durability).

Bi-metal reciprocating saw blades can tackle applications that have a high demand for both toughness, and flexibility.

Tungsten Carbide (TC)-

This is the hardest of saw blade materials and the most expensive. Although brittle, the extreme hardness of carbide is necessary for similarly extreme applications and sawing very dense materials.

[Back to top]

Additional Features

There are some additional reciprocating saw blade options and features worth mentioning that shoppers might encounter:

Tapered Back-

Recip saw blades with tapered backs are designed to help with plunge cuts, where the nose of the blade is used to start the cutting. This is accomplished by narrowing the blade toward the nose, and makes cutting in very tight spaces possible.

Specialty Blades-

There are numerous reciprocating blades for "specialty" applications that combine blade specifications and features in unique ways.

One of the most common kinds of specialty blades are those advertised for rescue and/or demolition. Because of the extreme application, rescue/demo. recip blades combine large measurements, the hardest materials, and can even be glow-in-the-dark.

Bi-Directional Blades-

A new design innovation for recip blades are teeth that cut in both directions. Considering the already present, two-way motion of reciprocating saws, this blade design is very energy efficient. It also provides very fast cutting.

[Back to top]

Conclusion

Is it time for a new reciprocating saw blade, or one that better matches your application? If so, visit eReplacementParts.com's Reciprocating Saw Blades page.

Our search features are streamlined to help customers sort through Power Tool Accessory options with speed. Search results narrow down when customers click the desired measurements or application features at the top of the page,

[Back to top]

What we're about.